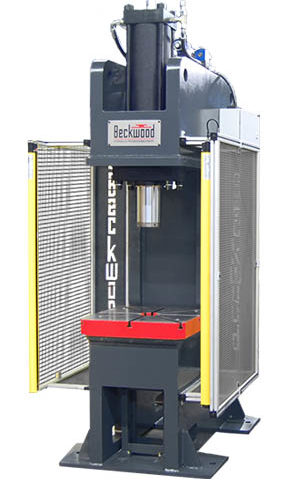

C-Frame Hydraulic Press Configuration

C-frame presses, also known as gap frame presses, offer 3-sided access to the working area to facilitate easy part loading and unloading as well as die maintenance.

Beckwood offers the following C-frame press types:

- Standard hydraulic benchtop presses up to 55 tons

- Standard servo-electric presses up to 50 tons

- Fully custom C-frame hydraulic presses up to 500+ tons

- Fully custom C-frame servo-electric presses up to 125 tons

Horizontal “Bulldozer” C-Frame Hydraulic Presses

When placed in a horizontal configuration, a C-frame press is referred to as a bulldozer press. These machines can accommodate extremely long parts loaded from either side as well as any bending or straightening application.

Bulldozer presses are designed to bend and straighten elongated stocks that are easier to load and unload horizontally. This includes I-beams for the railroad industry, alloys for aerospace parts, and chassis for off-road vehicles. Horizontal presses almost always have gib-guided rams to ensure maximum parallelism throughout the cycle despite off-center loading.

When faced with demanding bending and straightening applications, Beckwood’s side-acting bulldozer presses offer unmatched strength and durability. These robust presses are built for the specific tonnage, ram/bed size, speed, and control sophistication your application requires.

Benchtop C-Frame Hydraulic Presses

A benchtop hydraulic press is characterized by its compact footprint, production versatility, and relatively low-cost. To maintain cost-effectiveness while still offering ample tonnage, benchtop presses are usually offered in a C-frame configuration. Common uses for benchtop C-frame presses include material testing, general assembly, and forming of small parts. These models are available up to 55 tons, making them a great choice for applications where a small shop footprint is ideal.

C-Frame Linear Servo Presses

For operations requiring high precision, accuracy, and cleanliness, a C-frame press with servo-electric actuation is the preferred choice.

Servo-electric actuation can provide a host of many benefits for applications of all kinds. Servo-electric presses are known to boost performance, increase part quality, create an easy user experience, minimize maintenance and energy consumption, and facilitate safety in the workplace. Whether your work setting is a large-scale manufacturing plant or a small job shop, a servo-electric actuated C-frame press can help ramp up your production.

You can learn more about the benefits of servo-electric actuation here.

If you already have C-frame hydraulic press and are interested in converting it to a servo-actuated unit, you can read more about our hydraulic press retrofits here as well.

C-Frame Hydraulic Press Applications

Available in vertical or horizontal configurations for added flexibility, C-frame presses are ideal for virtually any low-tonnage application. Here are just a few industries where our hydraulic presses excel:

- Assembly

- Clamping

- Press Fitting

- Blanking

- Coining

- Embossing

- Forging

- Hot Forming

- Injection Molding

- Joggle Forming

- Punching

- Stamping

- Trimming

To give you a better idea of what our C-Frame hydraulic presses are capable of, we’ve compiled a few of our favorite examples of custom configurations that Beckwood has delivered to real clients like you.

Custom C-Frame Hydraulic Presses

Upright C-frame presses are a popular choice for low tonnage forming across a wide variety of applications, while horizontal bulldozer presses are often selected for use in high-tonnage applications. Here are just a few instances of custom C-frame hydraulic presses that Beckwood has delivered over the years:

35 Ton Hydraulic C-Frame Extrusion Press

This C-frame extrusion press was designed for use in the electronics industry. It uses low tonnage to extrude epoxy resin through a hole in the machine bed to create parts for circuit boards. A high-limit controller with one zone of heat is enhanced with the use of a customer-supplied Type K Thermocouple for maximum temperature control across the heated zone.

75 Ton C-Frame Press for Assembly

This custom c-frame press was engineered to assemble parts for use in the automotive industry. It utilizes an exclusive Regeneration Circuit for fast approach and retract modes to expedite the assembly process. This press is also equipped with an oversized oil cooling system to accommodate the high speed of operation.

150 Ton Punching C-Frame Hydraulic Press

Like the previous custom press, this custom C-frame press is also equipped with Beckwood’s exclusive Regeneration Circuit for expedited production. This model is used for general punching and forming of sheet metal parts in the manufacturing industry. Oversized bushings provide superior ram guidance and rigidity on 4 chrome housing posts to minimize deflection throughout the press cycle.

300 Ton Forming C-Frame Hydraulic Press

Lastly, this custom c-frame press was built for use in the transportation industry. It is used to form high-strength corrugated steel for railroad freight cars. Similar to our other custom C-frame hydraulic presses, this one has been equipped with Beckwood’s exclusive Regeneration Circuit to minimize production times.

460 Ton Hydraulic Bulldozer Press

This unique bulldozer press was engineered to serve the aerospace industry. It is used to bend, straighten, and form aluminum extrusions for the aerospace industry. An 8-point gib guidance system ensures maximum rigidity throughout the forming cycle.

See a Custom C-Frame Hydraulic Press in Action

Check out the video below which highlights the unique features of a custom C-frame extrusion press. A through-hole for scrap removal in the lower bed and a high-limit controller for in-die heating set this custom 35 ton C-frame hydraulic press apart from our standard models so that it can excel in its intended application.

This C-Frame hydraulic press implements the following custom features to suit reaction injection molding applications:

- (4) 4” diameter chrome-plate guide rods with self-lubricating bronze ram guide bushings

- Throat Distance: 8”

- Stripping Capacity: 2 tons

- 8” x 2” thru-hole machined in bed for part clearance

- High limit controller with 1 zone of heat works with customer-supplied Type K Thermocouple

- Skid-mounted power system and reservoir

- Kidney loop filter/cooler circuit with oversized thermostatically controlled fan motor

- Light curtains guarding front and side openings of the press

- Oversized oil cooling system minimizes risk for overheating

- Calculated Ram Speeds: Fast Approach 10 – 225 IPM; Pressing 1 – 100 IPM IPM; Return 10 – 180 IPM

If you think a C-frame hydraulic press would be right for your manufacturing and assembly needs, reach out to Beckwood today! Consult a Beckwood Engineer about your press needs.