HIGH PERFORMANCE METAL STAMPING PRESSES

Home » Applications » Metal Stamping

What Makes A Metal Stamping Press Different?

A metal stamping press, also known as a metal forming press or metalworking press, uses mated die sets to form, shape, mark, and cut metal. Stamping is a universal metalworking term that encompasses applications such as punching & blanking, embossing, perforating, coining & minting, and even general forming.

Crank Up The Heat with Hot Forming

Presses used for metal forming often feature heated elements to increase the malleability of the forming materials (blanks). When the press platens are outfitted with heating elements, the process is referred to as hot forming; and when the blank is heated before entering the press, it is called hot stamping. Adding heating capabilities to a metal stamping press can help decrease the amount of force required by the press to create the finished part, which results in cost savings during the design process as well as improved die life.

With our custom press engineering skills, we can pinpoint the ideal

press features to maximize the effectiveness of your metal forming

operations.

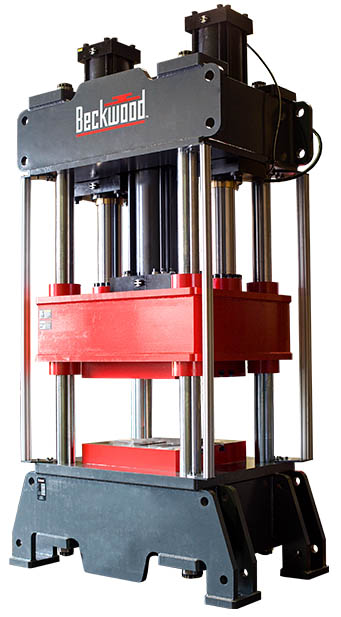

Presses for Metal Stamping Applications

Hydraulic presses and linear servo presses are ideal for metal stamping applications because they apply full tonnage throughout the entire stroke, not just at bottom dead center (BDC). This forming flexibility is particularly important when stamping high-strength metal alloys. Additionally, technologies like pre-fill valves and short-stroking are a great option on hydraulic metal forming presses to increase speed during the cycle. Precision and programmability are vital to creating the most efficient stamping operation and protecting your tooling and machinery from unnecessary wear.

Overcoming Metal Forming Challenges

Three primary challenges that you may encounter with a metal forming machine are breakthrough shock, precision, and efficiency.

Breakthrough shock is a sudden release of force at the bottom of the stroke when the die breaks through the material. It is often characterized by a loud boom and/or vibration which causes undue stress on the press and tooling. Beckwood’s Active Leveling Control technology counteracts the effects of breakthrough shock and springback by maintaining constant parallelism of the press ram throughout the entire stroke. This extends tool life and protects the press frame.

Precision and efficiency are common challenges because metal stamping is primarily performed on mechanical presses, which only reach full tonnage at the bottom of the stroke (BDC). That’s why Beckwood offers metalforming presses with servo-electric actuation. Servo-electric presses eliminate the crankshaft and flywheel and use electricity on-demand to create force at any point in the stroke. This added precision results in less scrap, energy cost savings, and improved part quality.

Bring us your challenge- and we’ll crush it.

Contact us today to get started.

Next-Gen Linear Servo-Electric Stamping Presses

While mechanical stamping presses offer the highest speeds of any pressing method, they have limited forming flexibility and are prone to double-hitting and sticking at bottom dead center (BDC). To combat these challenges, Beckwood developed a new line of Linear Servo Presses which achieve full tonnage anywhere throughout the stroke. This eliminates BDC and offers unmatched metal forming flexibility at production-level speeds.

Learn more about the benefits of servo presses for metal stamping applications

What About Hot Stamping?

Hot stamping is a specialized form of metal stamping in which the workpiece is heated by an external oven before it enters the press. This high heat greatly increases the malleability of the base material, which makes it easier to form complex geometries in a single pass. However, it requires a high tonnage to do so (compared to hot forming) along with a quenching step to rapidly cool the final part after it has been formed. Our robust metal stamping presses are engineered to excel in challenging applications like hot stamping, giving our customers the ultimate peace of mind that comes with press durability and reliability.