A hydraulic trimming press, also known as a cutting press, is used to debur, deflash, or otherwise remove excess material from workpieces after other forming or casting operations. It can also be used to cut large stocks into their finished shapes—sometimes in tandem with other forming operations like flanging. One advantage of hydraulic trimming presses is their ability to apply a high force, making them suitable for cutting and trimming even the toughest materials. Additionally, these machines are highly customizable and can be designed to meet specific production requirements. They are also relatively easy to maintain and operate, making them a popular choice for many manufacturing companies. From die-cast trimming metal pieces for automotive parts to steel rule die-cutting carpet, rubber, or foam, our application engineers understand the intricacies of your trimming and cutting operations.

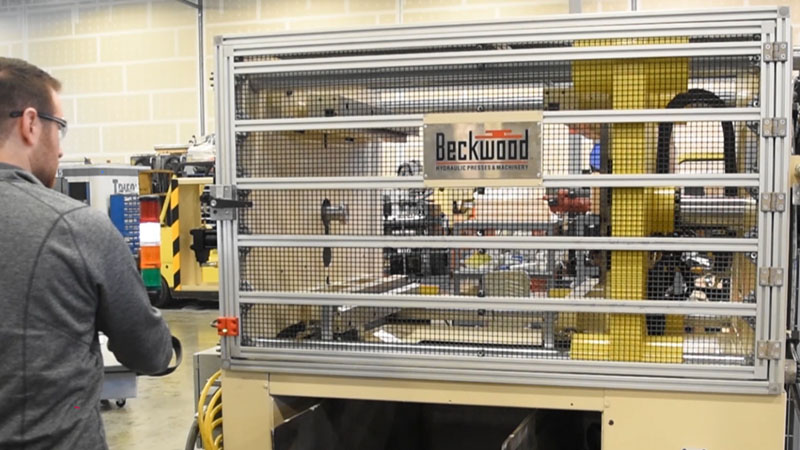

Beckwood trim presses are designed to remove excess material quickly and accurately, reducing the need for costly labor associated with manual trimming. Since trimming is typically a secondary process within a larger operation, our presses are able to easily integrate into any production cell to maximize your process efficiency.

Beckwood trims and die-cutting presses offer features including:

- Horizontal or vertical configurations

- Hydraulic or Servo-electric actuation

- Shuttles and belt systems for loading and unloading

- Conveyor systems and chutes for scrap removal

- Tilt tables

- Ejection cylinders

- Active Leveling Control for parallelism

- Programmable fixed stops for absolute position repeatability

Whether you need a custom trimming press or a light-duty standard model, we can help.

Consult a Beckwood engineer about your trimming and die-cutting press needs