Triform has expanded its product line with the addition of a 15,000 PSI Deep Draw Sheet Hydroforming press, featuring a 12” diameter maximum blank size and a 7” draw depth capacity. Read More

News Items will appear in the News section.

Triform has expanded its product line with the addition of a 15,000 PSI Deep Draw Sheet Hydroforming press, featuring a 12” diameter maximum blank size and a 7” draw depth capacity. Read More

Beckwood has expanded its Triform product line with the addition of extrusion and sheet stretch forming machines to support the manufacture of high-strength aerospace components. Read More

Beckwood has expanded its Triform line of aerospace forming equipment to include hydraulic ring expanders. The ring expansion process minimizes material thinning and virtually eliminates the stress point issues associated with traditional rolling and machining of engine turbine rings. Read More

A U.S.-based manufacturer of aircraft structures, airframe assemblies, and aerospace MRO, has ordered seven Triform presses from Beckwood. The comprehensive package, consisting of sheet hydroforming presses, stretch forming machines, and hot joggle presses, supports the customer’s mission of increasing its internal metal forming capabilities. Read More

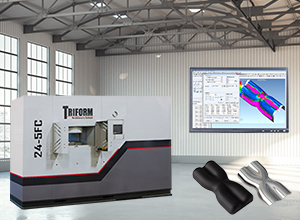

Beckwood has announced the commencement of a new educational circuit to inform individuals in the metal forming industry about new developments in rapid prototyping. The effort will focus specifically on the use of simulation software, 3D printed tooling, and Triform sheet hydroforming presses which can be used in conjunction to develop quality parts faster. Read More

Triform makes Variable Frequency Drives (VFDs) standard on all sheet hydroforming presses. A Variable Frequency Drive allows the press to draw energy “on-demand” and ramps up the motor only as needed – resulting in reduced energy consumption, noise, and heat. Read More

Beckwood has added a new Sales Engineer to their growing Sales & Marketing team. Caleb Dixon will serve as the lead salesperson for the Triform line of precision forming equipment, including sheet hydroforming presses, stretch forming machines, ring expanders, and joggle forming presses. Dixon will also support new sales for custom Beckwood machines. Read More

All Beckwood, Triform, and EVOx presses will now include the proprietary Presslink Remote Support Module to facilitate fast, easy troubleshooting, distance learning, and program updates to connect Beckwood technicians with presses in the field. Read More

With the goal of eliminating unplanned downtime, Beckwood Press Company has developed a Pre-Preventive Maintenance (PPM) technology which utilizes integrated machine intelligence to monitor the performance of Beckwood-manufactured equipment and automatically alerts key personnel as to the system’s status. Read More

Fike Corporation has awarded Beckwood a contract to engineer and build a custom hydraulic press for use in their Blue Springs, MO manufacturing facility. Due in late 2014, the press will be Fikes fourth custom Beckwood machine. Read More