Beckwood Press announces the creation of the Service Operations Department to enhance customer experience, and welcomes Richard Arthur as department director. Read More

News Items will appear in the News section.

Beckwood Press announces the creation of the Service Operations Department to enhance customer experience, and welcomes Richard Arthur as department director. Read More

Beckwood has closed a deal with one of the globe’s largest premier shipbuilders of both defense and commercial seafaring vessels. To match their scale, the 1,500 Ton four post press will include a large working area of 142″x183″ to provide the ultimate flexibility when it comes to the size of parts that will be produced. Read More

One metal spinning manufacturer is well on their way to modernizing their shop’s capabilities with their first TRIFORM deep draw hydroforming machine. An owner of numerous Cincinnati machines, this shop produces a wide mix of aerospace & defense parts from cabin components to satellite dishes. Read More

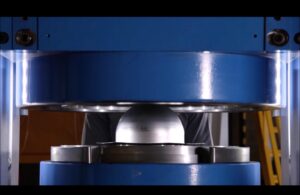

We are excited to announce an upcoming project to create a 250-Ton hydraulic ring expander for a first-time Beckwood customer. Not the type of hydraulic equipment you see every day, ring expanders act as a quick and reliable tool to size metal rings of all kinds. Read More

With an avid history of serving the defense industry, Beckwood’s latest project draws us back toward familiar territory in a newfound way. Our team is currently hard at work manufacturing a 500 Ton servo-electric press from our LSP line for a globally-renowned defense agency. Read More

Find out why our latest customer in aerospace selected Beckwood as their manufacturer for their newest equipment, a 30-Ton extrusion stretch forming press. Read More

Find out more about Beckwood’s latest contract with Hendrickson to create a second, fully-customized press to further expand their manufacturing capacity. Read More

Find out about Beckwood’s latest manufacturing contract with a return customer from the government aviation maintenance sector, to be delivered in late 2025. Read More

American automotive tool manufacturer, Lisle Corporation, is the latest to make the switch from traditional hydraulic machines to Beckwood's servo electric tech. Read More

Beckwood Press announces an expansion project to add 36,000 sq. ft. to their St. Louis, MO headquarters and manufacturing facility. Read More