Triform expanded their product line with several new deep draw sheet hydroforming models. The 20-10-10DD, 25-10-12DD and 32-10-12DD models represent a tremendous amount of knowledge gained over the past decade of hydroforming press manufacturing and include several key advantages over other available forming equipment. Read More

Lawrence Livermore National Laboratory ordered a Triform model 20-10-10DD deep draw sheet hydroforming press with a 20-in. diameter maximum blank size, 10,000 PSI of forming pressure, and a maximum draw depth capacity of 10 inches. Read More

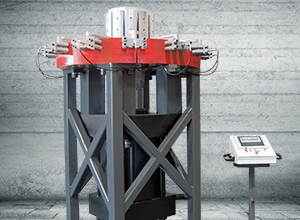

Oak Ridge National Laboratory (ORNL) awarded Beckwood a contract to manufacture a custom hydraulic press for the compression molding of various composite materials. The research and development performed with the press will ultimately contribute to automotive and aerospace industry lightweighting efforts, intended to produce higher performance products with improved fuel efficiency. Read More

Triform expanded its product line with the addition of a 10,000 PSI deep draw sheet hydroforming press, featuring a 20-in. diameter max blank size, 10-in.” draw depth capacity, and an integrated tool change system for fast change-over. Read More

Mohawk Industries has ordered a custom-engineered hydraulic rubber molding press system from Beckwood Press Company. To ensure Mohawk’s requirements for part thickness uniformity are met, the press will feature Beckwood’s proprietary Active Leveling Control (ALC) technology, which utilizes closed-loop control of the four press corners to ensure bed-to-ram parallelism is maintained throughout the cycle. Read More

Beckwood has been contracted to supply a custom hydraulic rubber pad press to U.S.-based sheet metal fabricating services provider, Milford Fabricating Company. The 400-ton press boasts a 38” x 60” forming area with a total pad thickness of 15” for forming on up to 5” tall form blocks. Read More

Triform recently installed a new deep draw sheet hydroforming press for Kreisler Manufacturing Corporation, a global provider of aerospace parts. The Triform model 16-10-7DD features a 16-in. diameter forming area, 10,000 PSI of pressure, and a 7-in. depth-of-draw to produce a variety of high-performance aircraft and aerospace engine parts. Read More

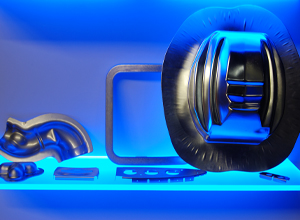

Triform has expanded its product line with the addition of a 15,000 PSI Deep Draw Sheet Hydroforming press, featuring a 12” diameter maximum blank size and a 7” draw depth capacity. Read More

Beckwood has expanded its Triform product line with the addition of extrusion and sheet stretch forming machines to support the manufacture of high-strength aerospace components. Read More

Beckwood has expanded its Triform line of aerospace forming equipment to include hydraulic ring expanders. The ring expansion process minimizes material thinning and virtually eliminates the stress point issues associated with traditional rolling and machining of engine turbine rings. Read More