Learn how Pryer Aerospace overcame the barriers to hot forming titanium and won new aerospace contracts. Read More

Success Stories will appear in the Success Stories section.

Learn how Pryer Aerospace overcame the barriers to hot forming titanium and won new aerospace contracts. Read More

A global manufacturer of transformers needed to repair and relocate a 10-year-old press. After only 3 weeks, the customer received a re-built press with several major upgrades to ensure continuous production and reliability for years to come. Read More

“At double the tonnage of our other triple-action presses and with a larger bed size, we’ve already increased capabilities by 50%. Ease of use due to programmability should push capabilities to a 60-70% increase.” Marshall Rugg, Weldmac Read More

With the Automated Die Storage & Retrieval System, this aerospace customer reduced changeover time from 2 hours to 10 minutes, adding 3.5 hours of production during a typical 8 hr shift. Read More

“Our presses have functioned accurately and reliably for many years, and our operators like the standardized interface Beckwood works with us to create on each machine." Rob White, President, Dahlstrom Roll Form Read More

"We chose Beckwood because they they could tailor a press to meet our requirements and handle the different materials we wanted to form," said Ken Kolman, quality manager at Columbia Metal Spinning. Read More

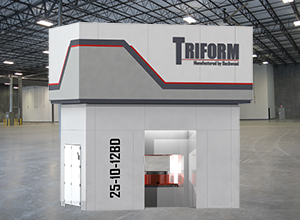

“The Triform team is very supportive,” said Victor Chung, Managing Director at Jinpao. “Their Sales, Application and Engineering teams are very helpful to a new-entry company in this industry. We ultimately chose Triform because of their total solution.” Read More

Empire ultimately chose Beckwood because they build highly customized, American-Made machinery that can integrate well with current systems. "That was a deciding factor for us," said Steve Lallensack, Director of Operations at Empire Level. Read More

“With the success we have had with the hydroforming press on the A320 program, Aerosud is now working on the design for the Airbus A350 Slat Track Cans using the press.” - Dr. Leon Labuschagne, Director of Technology for Aerosud Holdings Read More

Using their Triform deep draw sheet hydroforming press, this manufacturer was able to eliminate spring back, scrap, manual handwork, and wrinkles. The Triform press has automated manufacturing operations so successfully that it's saved a total of 55 minutes in the production of each of these parts. Read More