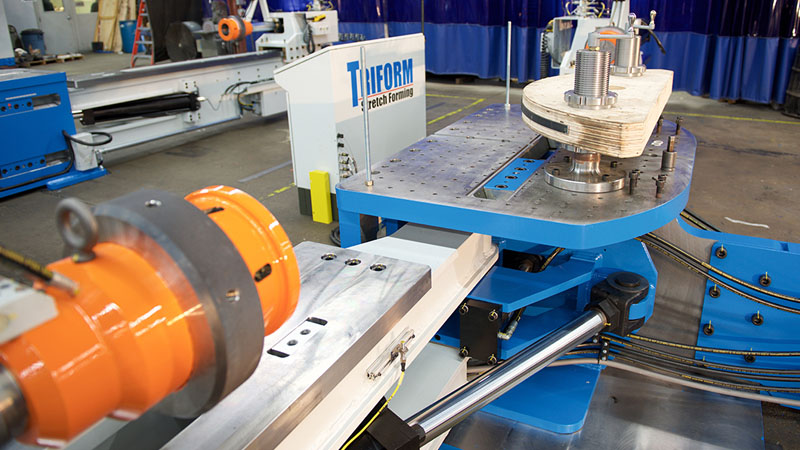

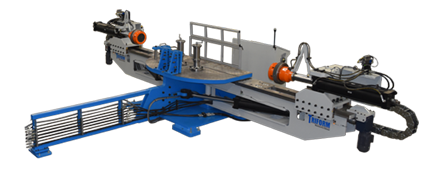

| Tonnage | 30 | ||

| Application | Stretch Forming | ||

| Industry | Aerospace | ||

| Frame Style | Non-traditional | ||

| Special Features | • Pre-Preventive Maintenance Package • Closed-Loop Chiller System • Hydraulic Joggle Ram | ||

| Intended Use | Used to form aluminum extrusions for airplane wing stringer |

Custom Features:

- Jaws: 8” Extrusion (manually rotatable 180°)

- Close Capability: 10”

- Tension Cylinder Stroke: 30”

- Tension Cylinder Speed: 1-30 IPM (Programmable)

- Swing Angle:10 Degrees Forward / 90 Degrees Backward

- Maximum Operating Pressure: 3,010 PSI

- Hyperchill closed-loop chiller system

- On-Board Pre-Preventive Maintenance System for maximum time

- Motorola barcode scanner included for quick recipe recall

- Expanded metal mesh perimeter guard will surround the stretch press area

- 5-Ton hydraulic joggle ram is provided to perform joggle bends in the formed extrusions