What is Bulge Forming?

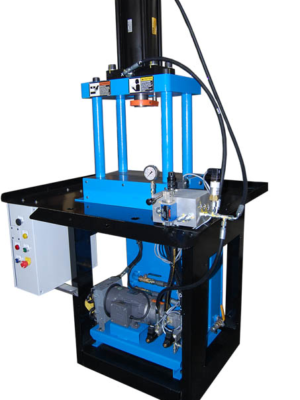

Bulge forming presses are sophisticated, high-tonnage clamps that apply force to the tooling to counteract the pressure being injected into the forming chamber. During the bulge forming process, operators insert a blank into a mold mounted inside the press and introduce pressure, either air or water, into the chamber. The pressurized media forms the material to the shape and contour of the tool.

Bulge Forming Press Uses

A bulge forming press is ideal for manufacturing large, domed parts from a variety of materials including aluminum, steel, and other high-strength alloys. Unlike deep-drawn parts, bulge formed parts are typically much more shallow and larger in diameter. Bulge forming is becoming increasingly popular among aerospace, automotive, and oil & gas manufacturers because of its ability to use air or water to produce complex, seamless, lightweight, “near-net-shape” parts. Bulge forming is most commonly used to form tank heads and rupture discs with uniform wall thickness and very little scrap.

Types of Bulge Forming Presses

The two primary types of bulge forming are air (pneumatic) and fluid (hydro). Pneumatic bulge forming presses (using air or gas) are most often used to form spherical shapes such as discs or tank heads whereas fluid bulge forming (hydro) is typically used to form cylindrical shapes such as tubes or canisters. These machines vary widely in size and tonnage, but it is not uncommon to see bulge forming presses with more than 2,000 tons of force.

Consult a Beckwood engineer about a bulge forming press

Learn how Fike Corporation uses its bulge forming presses to increase production