With an avid history of serving the defense industry, Beckwood’s latest project draws us back toward familiar territory in a newfound way. Our team is currently hard at work manufacturing a 500 Ton servo-electric press from our LSP line for a globally-renowned defense agency. Read More

One metal spinning manufacturer is well on their way to modernizing their shop’s capabilities with their first TRIFORM deep draw hydroforming machine. An owner of numerous Cincinnati machines, this shop produces a wide mix of aerospace & defense parts from cabin components to satellite dishes. Read More

Beckwood has closed a deal with one of the globe’s largest premier shipbuilders of both defense and commercial seafaring vessels. To match their scale, the 1,500 Ton four post press will include a large working area of 142″x183″ to provide the ultimate flexibility when it comes to the size of parts that will be produced. Read More

Beckwood is now offering all-electric linear servo actuators on any hot forming or superplastic forming press up to 500 tons. Read More

Beckwood to build 1500-ton hydraulic stamping press for Hendrickson USA that will blank, draw, and form parts for the transportation industry. Read More

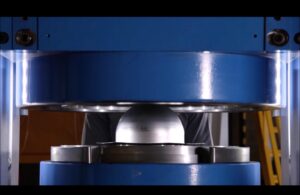

Beckwood launches new linear servo press line with the highest tonnage capacity on the market. Read More

Beckwood Press Company expands their stretch forming line to include standard extrusion stretch forming machines to replace existing Hufford presses. Read More

Beckwood Press Company has partnered with steel tube and pipe manufacturer Bull Moose Tube to build an Ascent press. Read More

Beckwood Press Company has been awarded a contract by MuShield to engineer and build a Triform hydroforming press 16-15-7DD. Read More

Beckwood Press Company fosters growth by expanding leadership with a new engineering manager and supply chain manager. Read More