-

Servo Press Benefits

Servo presses offer several benefits over hydraulic and mechanical presses. Increased accuracy, precision, and energy efficiency coupled with lower maintenance and operating costs are the primary reasons OEMs choose servo presses. Read More

-

Titanium Forming Methods

Learn about the various titanium forming methods including cold forming, hot forming, and superplastic forming. Discover how to choose the best method and machinery for your operation. Read More

-

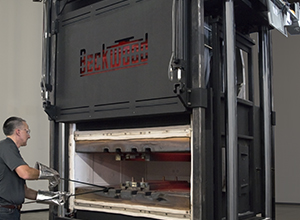

Triple-Action Press Increases Aerospace Supplier’s Production Capacity by 60% – Weldmac

“At double the tonnage of our other triple-action presses and with a larger bed size, we’ve already increased capabilities by 50%. Ease of use due to programmability should push capabilities to a 60-70% increase.” Marshall Rugg, Weldmac Read More

Teach Me Anything

Trends and Technology for the Future of Manufacturing