Medical Forming Presses and Machinery

In medical device manufacturing, there’s no room for error. Accuracy, precision, and cleanliness are paramount, and part quality and traceability must be maintained throughout the entire manufacturing process. That’s why Beckwood offers an array of machinery designed specifically for medical supply manufacturing.

Whether you’re assembling cathodes into pacemakers or forming artificial joints from titanium, our presses and automation systems ensure every part you make is ready for the job. Below are just a few of the ways our medical forming machinery can give you a competitive edge:

EVOx™

Ideal for low-tonnage forming and assembly applications in labs and clean room environments, EVOx™ servo-electric presses offer unmatched accuracy and precision without using hydraulics. Every EVOx press boasts positional repeatability within ±0.0005” and an open-architecture programming structure for easy recipe setup and R&D. Additional options for heat, dwell, and safety can be included on any EVOx™ press for maximum forming flexibility.

TRIFORM™

Beckwood’s TRIFORM™ sheet hydroforming presses thrive in low-volume, high-mix production environments where tool changes occur frequently and manufacturing processes are continually refined. Sheet hydroforming presses use a pressurized rubber diaphragm and a single, un-mated tool to create near-net-shape parts in just one cycle. TRIFORM’s proprietary In-Sight tool even allows you to view forming progress at any point throughout a cycle and adjust the recipe to achieve optimum forming results. This feature greatly expedites R&D and reduces costs and scrap.

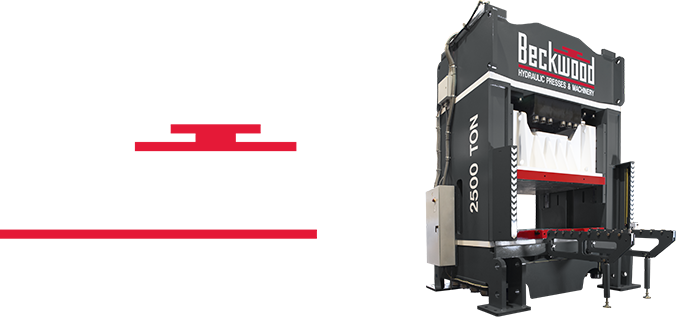

Custom Hydraulic Presses

Custom hydraulic presses are well-suited for applications requiring more than 200 tons of force or lower accuracy tolerances. Like servo-electric presses, they can achieve full tonnage anywhere throughout the stroke and are fully configurable to achieve your production goals.

Additional Resources

EVOx Servo Presses Deliver Unmatched Precision

Medical Industry Guide

White Paper

Medical Developments

Article