Hydraulic Presses Engineered for Efficiency

Beckwood’s Ascent™ line of standard hydraulic presses is pre-engineered for fast shipment and cost efficiency. Through our standardization of the press designs, Ascent™ customers can reduce their lead times by up to 70% compared to custom machinery at a lower cost, without sacrificing quality or performance. Our Ascent™ models are now available faster than ever before, with a delivery time as little as just 12 weeks.

The Hidden Costs of A Used Hydraulic Press

Used hydraulic press equipment naturally comes at a lower price point than buying new, which makes them an enticing choice from a purchasing perspective. However, what buyers don’t see hiding behind that that lower price tag are thousands of dollars of potential costs that only arise once the machine is in use. Poor maintenance history, true tonnage capacity, and forming accuracy (or inaccuracy) can all be cleverly hidden or conveniently omitted until it’s far too late to ask for a refund.

We designed the Ascent™ line to serve as a cost-effective alternative to used hydraulic presses that often come with hidden costs. Now you can get reliable quality, speedy delivery, and a pleasant price point, all without any of the risks that come with buying used.

The Hidden Costs of A Used Hydraulic Press

Used hydraulic press equipment naturally comes at a lower price point than buying new, which makes them an enticing choice from a purchasing perspective. However, what buyers don’t see hiding behind that that lower price tag are thousands of dollars of potential costs that only arise once the machine is in use. Poor maintenance history, true tonnage capacity, and forming accuracy (or inaccuracy) can all be cleverly hidden or conveniently omitted until it’s far too late to ask for a refund.

We designed the Ascent™ line to serve as a cost-effective alternative to used hydraulic presses that often come with hidden costs. Now you can get reliable quality, speedy delivery, and a pleasant price point, all without any of the risks that come with buying used.

All Beckwood presses are backed by our quality guarantee.

Get a quote on an Ascent™ model today.

Experience Our Infinite Life Hydraulic Press Technology

All Ascent™ models feature a gib guided frame designed to the Infinite Life classification for ultimate precision and rigidity. With models ranging from 100 tons to 400 tons, a wide range of frame sizes, and options for added safety and uptime, this line is highly customizable to meet the demands of any manufacturing facility. No matter the industry or forming process, an Ascent™ press will improve your production.

Experience Our Infinite Life Hydraulic Press Technology

All Ascent™ models feature a gib guided frame designed to the Infinite Life classification for ultimate precision and rigidity. With models ranging from 100 tons to 400 tons, a wide range of frame sizes, and options for added safety and uptime, this line is highly customizable to meet the demands of any manufacturing facility. No matter the industry or forming process, an Ascent™ press will improve your production.

Reliable American Made Quality

All Ascent™ presses are manufactured, serviced, and supported in the USA by our industry-leading team of factory-trained experts, so you can rest assured knowing your press is backed by Beckwood.

Reliable American Made Quality

All Ascent™ presses are manufactured, serviced, and supported in the USA by our industry-leading team of factory-trained experts, so you can rest assured knowing your press is backed by Beckwood.

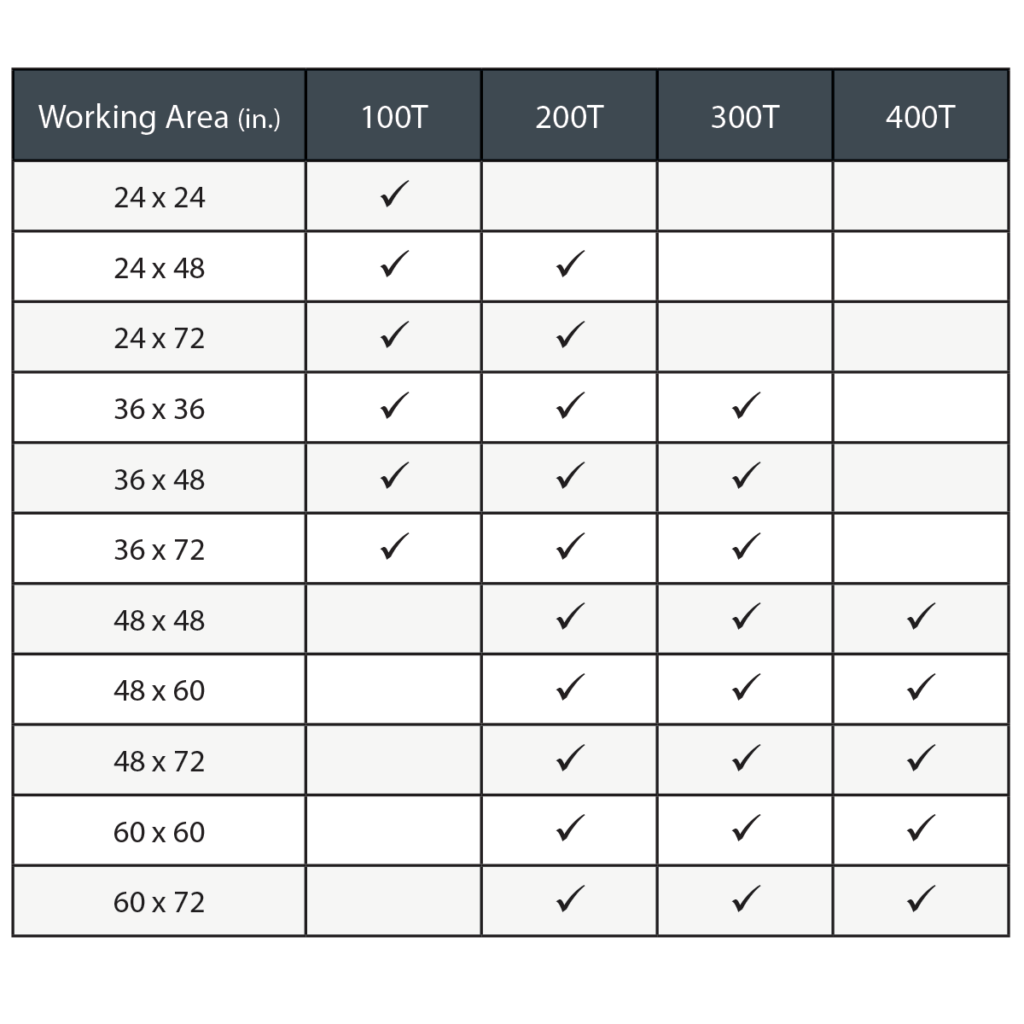

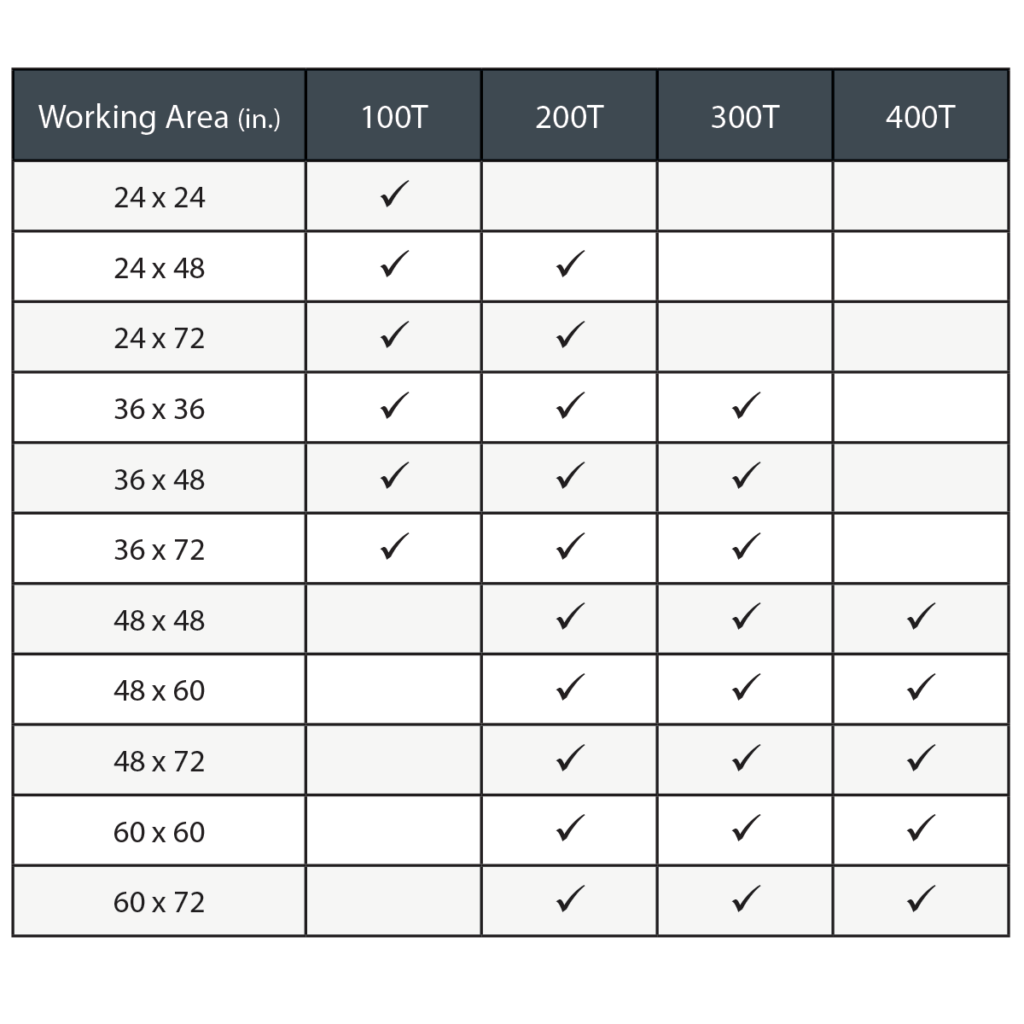

Standard Hydraulic Press Configuration Options

Our Ascent™ standard press machines are available in 29 unique working area configurations to provide our customers with a broad range of quick-ship solutions for their forming and assembly needs. Available configurations are as follows:

Standard Hydraulic Press Configuration Options

Our Ascent™ standard press machines are available in 29 unique working area configurations to provide our customers with a broad range of quick-ship solutions for their forming and assembly needs. Available configurations are as follows: