A Hydraulic Press Manufacturer that Designs for Your Needs

Here at Beckwood we’ve earned a solid reputation in the industry for our specialization in the development of custom hydraulic press solutions. That reputation stems from our unwavering dedication to solving our customers’ unique needs, whatever those needs may be. Our engineering team loves a good challenge, so we encourage our customers to bring their biggest head scratchers to us- and we guarantee solutions that work.

While a custom hydraulic press often provides our customers with the exact solution they’re looking for, the development of a one-off, custom press solution takes time. Some customers simply don’t have the luxury of waiting on extensive lead times- they need their press as quickly as possible. Beckwood saw this gap in the market and took to developing a solution that could meet our customers’ time constraints without compromising on our renowned Beckwood Tough quality.

We pride ourselves on being more than just another hydraulic press manufacturer. At Beckwood we strive to be a reliable business partner to every customer that we serve. With this commitment in mind, Beckwood has developed a line of standard hydraulic presses to deliver quick, effective solutions to our partners who need them. From the minds of Beckwood engineers and creatives across all departments: let us introduce you to our Ascent line of hydraulic presses.

Ascent Hydraulic Presses Are Pre-Engineered to Save Time

We may call the Ascent our “standard” line of hydraulic presses, but at Beckwood we hold ourselves to a higher standard than most. These hydraulic presses have been pre-engineered to minimize lead times and maximize cost efficiency, all with our press technology that’s backed by decades of expertise across a wide breadth of industries. You can count on our Ascent presses for high performance and forming versatility to suit any and all of your pressing needs.

Our Ascent presses are available with a wide variety of features including more than 20 different frame styles. These frame styles are designed to accommodate a large range of working areas from as small as 24”x24” to as large as 60”x72”. Every Ascent hydraulic press frame is engineered for infinite life thanks to a unitized gib-guided frame which also ensures the highest possible level of ram precision and ram-to-bed parallelism.

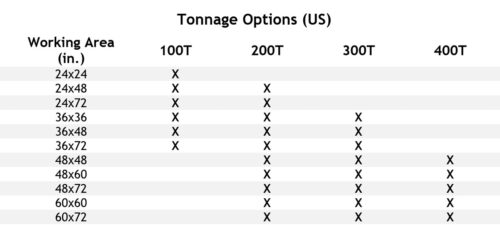

Ascent presses can be equipped to handle a tonnage as low as 100 tons to as high as 400 tons. Each tonnage model is available in a multitude of frame sizes, providing you with a range of options to meet your specific process needs:

- Ascent 100 Ton Hydraulic Press

- 6 frame sizes

- Ascent 200 Ton Hydraulic Press

- 10 frame sizes

- Ascent 300 Ton Hydraulic Press

- 8 frame sizes

- Ascent 400 Ton Hydraulic Press

- 5 heavy duty frame sizes

As for bed sizes, we have put together this handy chart for our most popular Ascent models:

By selecting a standard hydraulic press from our Ascent line, you can expect lead times that are significantly shorter compared to custom presses. In some cases, Ascent hydraulic presses can reduce costs and lead times for our customers by up to 50%.

Our engineers don’t just meet expectations. We exceed them.

Contact Beckwood today to get a quote on your Ascent standard hydraulic press.

Contact Beckwood Press

Ascent Hydraulic Presses in Industry

In real-world industrial manufacturing applications, time is money- and the Ascent hydraulic press line is designed to help you save. Customers across a variety of industries including consumer goods, energy, HVAC, automotive, and more have enjoyed the time saving benefits of a pre-engineered Ascent press. Learn how the Ascent is used in industry applications including job shops and the automotive industry.

Ascent Hydraulic Presses for Job Shops

Job shops by design face a wide range of challenges with something new every day. This high mix production style demands a press that has the forming flexibility to handle a varied workload and sometimes perform a multitude of different functions. The Ascent line is equipped to not just meet the needs of job shops, but exceed them.

For job shops, Ascent hydraulic presses are well equipped to handle common forming operations including:

- Metal forming

- Bending & Straightening

- Punching & Blanking

- Stamping

- Trimming

- And more!

Our hydraulic presses aren’t just for forming parts either. In one Texas tubing manufacturing facility, a 100-ton Ascent hydraulic press is used to pressure test weld seals for steel tubing.

Whatever the application may be, Beckwood’s Ascent hydraulic presses are designed to minimize operator fatigue, boost dimensional accuracy, improve part forming repeatability- and then some.

Ascent Hydraulic Presses in Automotive Industry

With a wide range of available tonnage ratings, Ascent hydraulic presses can find their place in many facets of the automotive manufacturing industry.

Lower tonnage hydraulic presses are ideal for forming interior components like foam padding for seats and plastics for dashboards, consoles, door cards, and more. The higher tonnage options are best suited for forming metal components like body panels. Like in the job shop industry, Ascent hydraulic presses can also be utilized to pressure test components. In assembly operations, these presses can also be used to press fit components together as needed.

All in all, we are confident that we have engineered a solution that is cost-effective for customers across the board; can be delivered in a timely manner; and maintains the same level of quality that our customers have come to expect from Beckwood hydraulic presses.

“When we launched, our goal was to cut cost and lead times through pre-engineered, standard machinery… We are excited to see the benefits of the Ascent line come to fruition.” – Gerard Choinka, Beckwood Sales Engineer

Ascent Standard Hydraulic Presses: Built Beckwood Tough.