Get Unmatched Versatility With A Benchtop Press

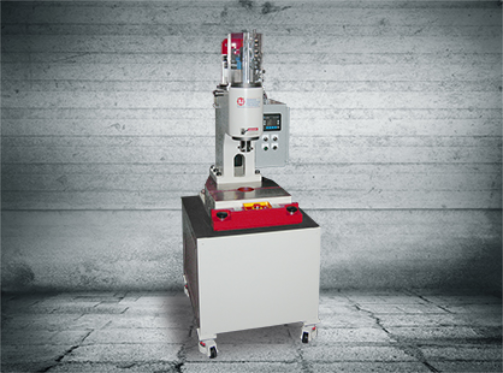

A benchtop hydraulic press is characterized by its compact footprint, production versatility, and relatively low cost. Typically offered in a c-frame configuration, these presses are commonly used for laboratory work, small-scale production, or research and development. This covers an expansive variety of applications beyond metal forming including material testing, sample preparation, pressing and forming of small parts, and general-purpose assembly and disassembly operations.

What Makes DJ Different?

DJ benchtop hydraulic presses by Beckwood are standardized for quick shipment and cost effectiveness. Yet, each unit can also be customized for key process parameters including stroke, shut height, daylight, and speed to meet your manufacturing, assembly, or testing needs.

Our c-frame benchtop models range from 3 to 55 tons, so you’re sure to find the right style for your application. Additionally, these machines integrate seamlessly with ancillary equipment like coil feeders, robots, conveying systems, and more, so creating an automated production workcell is simple.

Need a hand with workcell configuration? Ask about our automation capabilities to find out what Beckwood can do for you.

Advantages of a Beckwood DJ Benchtop Hydraulic Press

- Backed by Beckwood’s factory-trained service & support team

- Cost-effective entry point to the Beckwood ecosystem

- Small footprint for efficient shop space utilization

- Rigid construction for long-lasting performance

- Suitable for a variety of applications

- Standard & customizable configurations including frame style, tonnage capacity, and more

- Automation and workcell integration

- Three-sided access to the operating area for easy die maintenance, part loading, and scrap removal

- Light curtains, guards, and additional safety features available

Consult a Beckwood engineer

about your benchtop press needs today.

Advantages of a Beckwood DJ

- Backed by Beckwood’s factory-trained service & support team

- Cost-effective entry point to the Beckwood ecosystem

- Small footprint for efficient shop space utilization

- Rigid construction for long-lasting performance

- Suitable for a variety of applications

- Standard & customizable configurations including frame style, tonnage capacity, and more

- Automation and workcell integration

- Three-sided access to the operating area for easy die maintenance, part loading, and scrap removal

- Light curtains, guards, and additional safety features available

Consult a Beckwood engineer about your benchtop press needs today.

DHS-R ModelRam-Guided Benchtop Hydraulic Presses

DHC ModelsBenchhtop Hydraulic Presses with Iron Frames

EVOx Models

Servo-Electric Benchtop Presses

Servo-Electric Benchtop Presses

DHS Models

Benchhtop Hydraulic Presses with Steel Frames

Benchhtop Hydraulic Presses with Steel Frames

DBP Models

Benchtop Pneumatic Presses

Benchtop Pneumatic Presses

Custom C-Frame Presses