Why Choose a Custom Hydraulic Press?

Our custom hydraulic press manufacturing capabilities allow our customers to break free of the limitations that come with standard press models. A custom press engineered for your specific application will last longer and work for more efficiently than a standard model, because it’s doing exactly what it was made to do. With higher efficiency, improved part production, and a longer life cycle ensured by Finite Element Analysis (FEA), custom press owners often see a significant return on investment throughout the life of the machine.

How Beckwood

Tackles Your Challenges

At Beckwood we are first and foremost an engineering company and have custom hydraulic press engineering down to a science. Our proven 4-step process is what guides us through designing, crafting, and refining the ideal press to tackle your forming challenges. Here’s what you can expect when you choose Beckwood to manufacture your custom hydraulic press.

Finally, the most exciting part: your brand new custom hydraulic press gets delivered directly to your facility. A Beckwood engineer will be on-site to supervise the assembly of your new equipment. Once the press has been put together and tested for performance, our engineer will guide your personnel through everything they need to know about operating your machine. After installation and training are complete, the Beckwood team is always just a call away to provide support for a lifetime.

See a Beckwood Custom Hydraulic Press in Action

Check out this video which highlights the unique features of a custom deep draw hydraulic press that we manufactured for Columbia Metal Spinning. In our test shown here, we form an aluminum sheet with a hemispherical die. At CMS, they are primarily using the press to form Inconel, aluminum, and brass nickel into hemispheres and flared tube ends. With a 54” x 54” forming area and a 120-ton hydraulic bed cushion, the new press expanded the job shop’s large-diameter draw forming capabilities.

Custom Press Success Stories

Empire Level

• 450 Ton Custom Hydraulic Press

• Custom Press Features:

• 8 Point Gib-Guided System

• QDC System

• ANSI B11.2 Compliant

“Beckwood was able to design, engineer, and build a custom press for our specifications from their factory in St. Louis, MO. That was a deciding factor for us.” – Steve Lallensack, Director of Operations at Empire Level

Your Success Story Could Be Next.

with a custom hydraulic press and contact Beckwood today.

Custom Hydraulic Press Features

Beckwood hydraulic presses are designed with custom features to meet the needs of your specialty applications. From compression molding to forging and assembly to automation, your manufacturing processes can be enhanced with the right combination of our system capabilities. Here is some of the technology that we use to take your custom press capabilities to the next level:

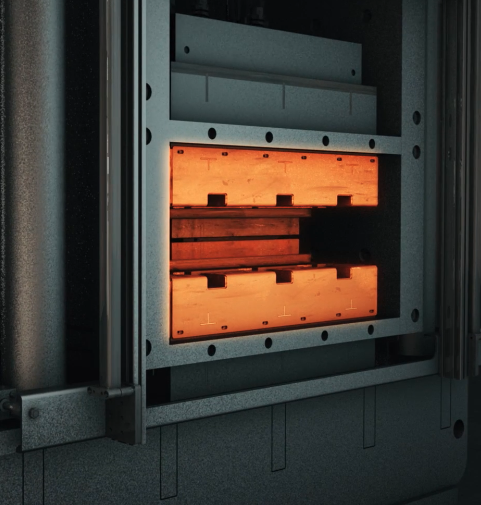

Heated Platens

Electric, oil or steam heated platens can be provided for hot forming capabilities. Whether it is just a few hundred degrees or 2,000 degrees Fahrenheit, Beckwood has your hot press solution. For superplastic forming (SPF) applications, an argon gas management system can be added. Conversely, cooling platens or chill plates can also be integrated as needed.

Dynamic Bed Cushion Control

Beckwood’s dynamic bed cushion controls allow for tonnage adjustments throughout the entire draw cycle, resulting in greater flexibility when it comes to varying raw material grades and inconsistencies. This provides higher part quality and minimal defects such as tears. Our custom presses can be equipped with dual or triple-action drawing as well.

Active Leveling Control (ALC)

Our active leveling control (ALC) technology works to actively maintain bed-to-ram parallelism to minimize the effects of off-center loading. High speed closed loop motion control and hydraulic servo components ensure performance for the most demanding custom applications.

Quick Die Change (QDC) Systems

For the ultimate efficiency in high-mix production, quick die change (QDC) systems empower operators to spend less time adjusting tooling and more time forming new parts.

Linear Servo-Electric Actuation

Linear servo-electric actuation eliminates the use of hydraulic fluid entirely, making it the ideal technology to employ in today’s modern manufacturing applications.

Additional Safety Features

There are many safety features baked into every Beckwood Press, but for added protection we also offer safety features like light curtains, physical guarding, a ram safety catcher system, and more.

Non-Traditional Custom Press Frame Styles

Our custom hydraulic press frames are available in the most common gib guided, 4-post, 2-post, and C-frame configurations- but what about cases where those frames just won’t cut it? Along with our standard frame styles we also offer a selection of totally customizable non-traditional hydraulic press frames for specialty applications. This is just a sample of what we can do.