What is Stretch Forming?

Stretch forming is a type of metalworking most commonly used in aerospace applications. During the metal stretch forming process (also known as ‘wrap forming’), metal sheets or extrusions are stretched to exceed their inherent elastic limit and formed around contoured dies to create the desired shape. This “stretching” results in an increased material yield strength and a stronger finished part. Since stretch forming machines maintain constant tension of the metal throughout the process, they minimize imperfections and wrinkles.

This process can produce parts of varying complexity, from a simple curved part such as an aircraft skin to one with intricate geometries consisting of non-uniform cross sections. Most leading edge parts, joined structural sections, and contoured trim are created using a stretch forming machine.

Types of Stretch Forming

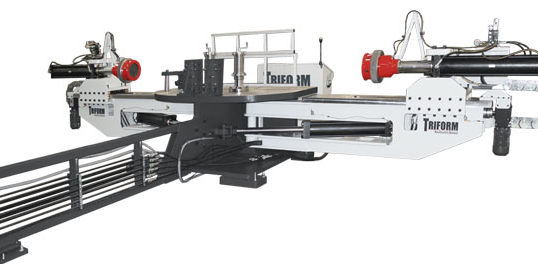

Triform designs and builds machines for two main types of stretch forming: sheet (transverse) and extrusion (longitudinal).

In sheet stretch forming, a large sheet metal blank is placed atop the die or stretch form block. The blank is held in place by gripping jaws which hold the edges of the sheet metal. During the cycle, the stretch form block (die) moves upward and pushes against the sheet until it forms into a contoured shape. Features like oscillating carriages enable the machine to form a variety of complex bends and angles in one cycle. Sheet stretch forming machines are most commonly used to form large metal panels for the aerospace and transportation industries. See a Sheet Stretch Forming Machine in action.

In extrusion stretch forming, long pieces of metal (blanks) are clamped between circular gripping jaws which are attached to movable arms. A contoured die is mounted to a die table attached to the machine. During the cycle, the arms engage (either independently or simultaneously) to wrap the blank around the contoured die. The resulting aluminum extrusions are used primarily in the aerospace industry for wing stringers, chords, and other structural components. See an aluminum Extrusion Stretch Forming Machine in action.

Advantages of Stretch Forming

The main advantage of the stretch forming process is the ability to form large metal sheets and extrusions into complex shapes in a single cycle. Work hardening is a byproduct of the stretch forming process resulting in parts with a higher tensile strength and minimal springback. Since sheet and extrusion stretch forming machines use a single die, mated tooling is not required–saving up to 50% on tooling costs compared to traditional forming methods. Additionally, parts are free from scratches and scuffs, so secondary finishing is not required.

Features of Triform’s Extrusion Stretch Machines

- Synced or independent arm actuation

- Programmable pressure and position cycles facilitate both traditional and tangential stretch forming

- ‘Closed-loop’ control system allows precise, repeatable tension and angle control during operation: Arm Angle Control (±0.5 degrees) / Tension Force Control (±2% of full scale)

- Accurate, uniform tension force throughout the cycle minimizes wrinkling

- Programmable post-load cycle minimizes material spring back and increases the yield strength of material

- Built-in recipe functionality allows users to save proven cycle parameters for guaranteed repeatability and decreased set-up time

- Manual control mode gives the operator direct control over the cycle profile during new part development

- Supplemental accessories such as heat integration for high strength alloys and hydraulic joggle rams for setting bends in the formed extrusions can be incorporated as needed

Standard or Custom, We Do it All.

Beckwood offers both standard and custom stretch forming machines for extrusion stretch forming applications and fully custom designs for sheet stretch forming. Our standard models are designed to operate with existing Hufford form dies, so the transition to modern forming equipment is easy and seamless. Browse our standard stretch forming model list.