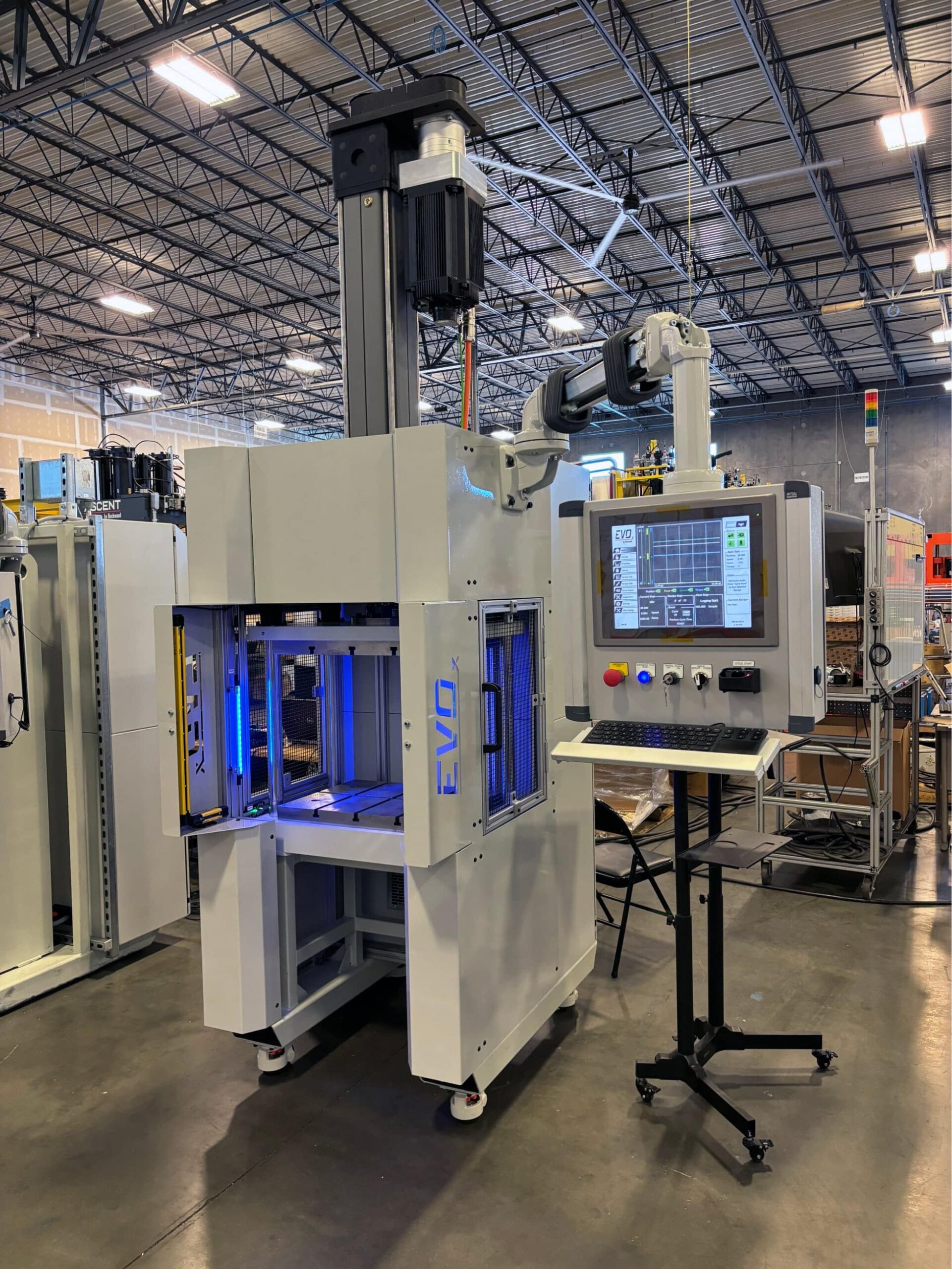

How EVOx™ Elevates Precision Metal Forming

How EVOx™ Elevates Precision Metal Forming

Servo-Electric Actuators Explained

Servo-electric presses use an all-electric linear actuation system in lieu of hydraulics or mechanical flywheels to precisely control the press ram throughout the entire stroke.

Unlike their hydraulic counterparts, linear servo-electric presses nearly eliminate the need for hoses, pumps, and most importantly, hydraulic oil. Removing hydraulic oil from press operations substantially improves workplace cleanliness, reduces part contamination, boosts energy efficiency, and increases operator safety- all while lowering operational and maintenance costs.

Our servo presses feature top of the line roller screw actuators. These linear actuators have been studied to last up to 15 times longer and achieve greater load capacity than more commonly used ball screw servo actuators like those found in competitors’ servo machinery. That’s just the beginning. If you want to know more about why servo-actuation is the best thing in metal forming since hydraulics, click here to discover more about the benefits of our linear servo presses.

What Makes Our Servo Presses Beckwood Tough?

We use Six Sigma and 5S Lean Manufacturing Techniques to optimize our quality control process and improve the consistency, reliability, and efficiency of every electric press we build. Our Quality Management System allows us to measure process variations, develop new systematic procedures, and ultimately, increase customer satisfaction with presses that are built to last.

Our servo-electric presses aren’t just durable- they’re Beckwood Tough.

What Makes Our Servo Presses Beckwood Tough?

We use Six Sigma and 5S Lean Manufacturing Techniques to optimize our quality control process and improve the consistency, reliability, and efficiency of every electric press we build. Our Quality Management System allows us to measure process variations, develop new systematic procedures, and ultimately, increase customer satisfaction with presses that are built to last.

Our servo-electric presses aren’t just durable- they’re Beckwood Tough.