| Tonnage | 200 | ||

| Application | Other: Calibration | ||

| Industry | Automotive | ||

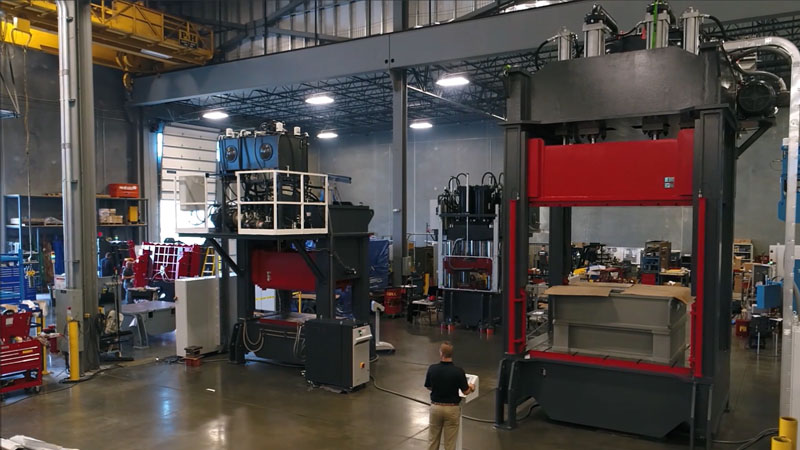

| Frame Style | Gib-Guided | ||

| Special Features | • Platens heated via hot oil system | ||

| Intended Use | Used in the automotive industry to calibrate plastic panels to the proper thickness prior to forming |

Custom Features:

- 8-point square gib-guidance system minimizes lateral movement under load

- (2) 39” x 67” platens heated up to 575-degrees F via a hot oil system

- Gun drilled channels in the platens create a serpentine flow for rapid cooling

- Skid mounted power system and reservoir

- Calculated Ram Speeds: Fast Approach:474 IPM, Pressing: 30 IPM, Return: 455 IPM