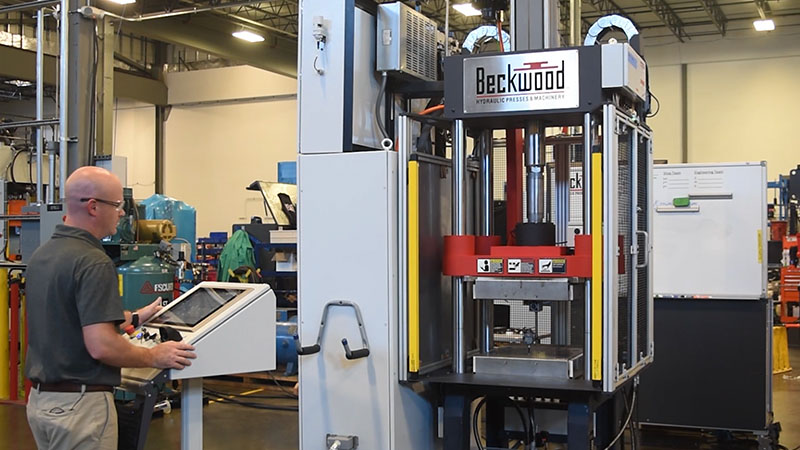

| Tonnage | 30 | ||

| Application | Compression Molding; Composite Forming | ||

| Industry | Construction | ||

| Actuator Type | Servo-electric | ||

| Frame Style | 4-Post | ||

| Special Features | • Infinite dwell capability • Electrically-heated platens | ||

| Intended Use | Used in a compression molding application to form carbon-fiber composites for the aerospace, automotive, & consumer goods industries |

Custom Features:

- (4) chrome housing posts with graphite impregnated bronze bushings for superior ram guidance and rigidity

- Servo-electric roller screw actuator from Exlar (no hydraulics)

- (2) 18” x 18” electrically heated platens with multiple zones of temperature control for ultimate uniformity

- Infinite dwell capability

- Productivity reporting tool

- Hydraulic pressure-controlled circuit with quick disconnect to accommodate customer tooling

- Light curtains guard the front openingsof the press; bolt-on expanded metal guarding on the sides and rear

- Calculated Ram Speeds: Approach 110 IPM; Pressing 50 IPM; Return 110 IPM