Beckwood LSP™ is a new era of press technology that combines the flexibility of hydraulic presses with the performance of servo-mechanical presses. Maintenance-free for millions of cycles, LSP™ offers precision, reliability, and efficiency to maximize your production.

Beckwood LSP™ is a new era of press technology that combines the flexibility of hydraulic presses with the performance of servo-mechanical presses. Maintenance-free for millions of cycles, LSP™ offers precision, reliability, and efficiency to maximize your production.

BENEFITS OF A LINEAR SERVO PRESS

Flexible Forming: Beckwood LSP™ offers precise control for complex draw work and stamping of high-strength alloys, ensuring maximum productivity and part quality with instant feedback.

Full Tonnage Throughout the Stroke: Linear servo presses maintain full tonnage at any point, eliminating the need to over-buy on tonnage and enabling long draws and strokes without de-rating.

Improved Die Handling: Extreme parallelisms extends tooling lifespan, while standard tonnage monitoring simplifies die setup and changeover.

Maintenance-Free: LSP™ all-electric actuation eliminates the need for many components, resulting in up to 60% fewer parts and long maintenance cycles.

Energy Efficiency: Hydraulic press systems consume a large amount of electricity, even during idle times. Linear servo presses use energy on-demand, yielding energy and cost savings of up to 70% compared to hydraulic presses.

Low Noise Output: By eliminating bulky components, LSP™ reduces noise levels, enhancing workplace safety and comfort.

Find the Right Beckwood LSP™ Press

Beckwood LSP™ is a new era of press technology that combines the flexibility of hydraulic presses with the performance of servo-mechanical presses. Maintenance-free for millions of cycles, LSP™ offers precision, reliability, and efficiency to maximize your production.

Beckwood LSP™ is a new era of press technology that combines the flexibility of hydraulic presses with the performance of servo-mechanical presses. Maintenance-free for millions of cycles, LSP™ offers precision, reliability, and efficiency to maximize your production.

BENEFITS OF A LINEAR SERVO PRESS

Flexible Forming: Beckwood LSP™ offers precise control for complex draw work and stamping of high-strength alloys, ensuring maximum productivity and part quality with instant feedback.

Full Tonnage Throughout the Stroke: Linear servo presses maintain full tonnage at any point, eliminating the need to over-buy on tonnage and enabling long draws and strokes without de-rating.

Improved Die Handling: Extreme parallelisms extends tooling lifespan, while standard tonnage monitoring simplifies die setup and changeover.

Maintenance-Free: LSP™ all-electric actuation eliminates the need for many components, resulting in up to 60% fewer parts and long maintenance cycles.

Energy Efficiency: Hydraulic press systems consume a large amount of electricity, even during idle times. Linear servo presses use energy on-demand, yielding energy and cost savings of up to 70% compared to hydraulic presses.

Low Noise Output: By eliminating bulky components, LSP™ reduces noise levels, enhancing workplace safety and comfort.

Find the Right Beckwood LSP™ Press

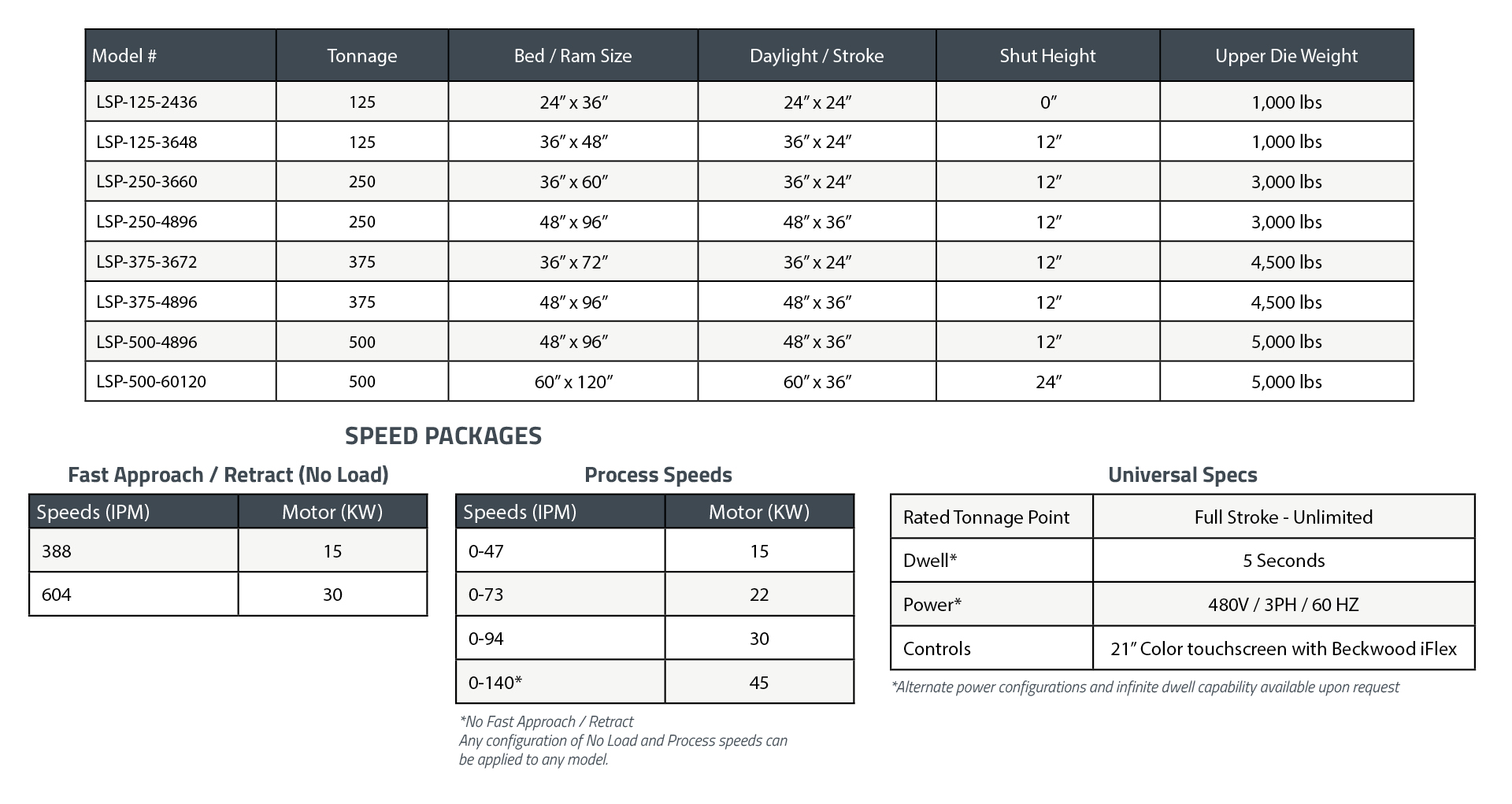

STANDARD LINEAR SERVO PRESSES

The Beckwood LSP™ product line features 8 standard models in an array of sizes, speeds, and tonnages.

Refer to the chart below for our standard model specifications.

STANDARD FEATURES

• 8 Point gib-guided unitized frame

• Vibration dampening pads

• T-Slots

• Data acquisition

• Recipe handling (1,000 capacity)

• 21” PC-based touchscreen

• Beckwood’s iFlex Controls

• Part quality monitoring

• Built-in ram Active Level Control (250T+)

• Overload protection

STANDARD FEATURES

• Light curtains & safety guarding

• Additional speed configurations

• Additional power configurations

• Infinite dwell

• Die protection

• Custom die mounting provisions

• Quick die change systems

• Complete press customization

SYSTEM SPECS

All Beckwood Presses Are Backed By Our Quality Guarantee.

Get a quote on a Linear Servo Press Today!

All Beckwood Presses Are Backed By Our Quality Guarantee.

Get a quote on a Linear Servo Press Today!

Sheet

Hydroforming

Equipment

Beckwood Custom

Hydraulic Press

EVOx Precision

Servo-Electric Press