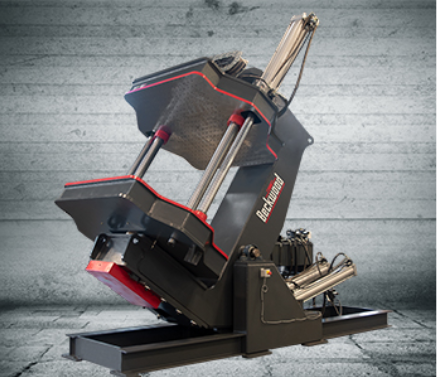

How far can Beckwood take press customization? See for yourself. We consistently champion the most unique builds with creative ideas, brought to life with precise engineering and unrivaled build quality. Below are a few examples of custom hydraulic and servo-electric presses with non-traditional frames that we engineered to meet the specific needs of specialized applications.

Why Choose A Custom Press Machine?

A custom press engineered for your specific application and production facility will give you a competitive edge and prove its ROI faster than you might think. Our custom press machines don’t just make your manufacturing possible– they make your capabilities better. Beyond just meeting your manufacturing needs with custom frame styles, custom-engineered presses can take your capabilities to the next level with improved accuracy, efficiency, safety, and uptime depending on the options chosen during the design phase.

Our Press Customization Expertise

Beckwood specializes in engineering and building custom presses for every manufacturing challenge. This often means designing solutions that do not fit within a standard configuration in order to meet the unique needs and space requirements of specialized manufacturing facilities. Whether you need a custom press that tilts and swivels for an injection molding application or one with electric actuators for high-precision forming, we are ready for the challenge.

it.

Why Choose A Custom Press Machine?

A custom press engineered for your specific application and production facility will give you a competitive edge and prove its ROI faster than you might think. Our custom press machines don’t just make your manufacturing possible– they make your capabilities better. Beyond just meeting your manufacturing needs with custom frame styles, custom-engineered presses can take your capabilities to the next level with improved accuracy, efficiency, safety, and uptime depending on the options chosen during the design phase.

Our Press Customization Expertise

Beckwood specializes in engineering and building custom presses for every manufacturing challenge. This often means designing solutions that do not fit within a standard configuration in order to meet the unique needs and space requirements of specialized manufacturing facilities. Whether you need a custom press that tilts and swivels for an injection molding application or one with electric actuators for high-precision forming, we are ready for the challenge.

Bring us your challenge, and we’ll crush

it.

Custom Press Frame FAQs:

What are the different types of hydraulic press frames?

Traditionally, there are 4 common press frame styles:

• 2-Post

• 4-Post

• C-Frame

• Benchtop

While these frame styles can accommodate the needs of many manufacturers, some projects call for a more unique configuration. In these cases, our design team will suggest a custom frame style such as a multi-post press, a side-acting press, or even something entirely new.

How do I choose the right press frame style for my application?

Our engineers collaborate closely with you to find the best press to meet your production needs, while keeping your manufacturing needs and press machine budget at top of mind. When choosing a press frame for a given project, we consider many key factors including:

• Tonnage needs

• Primary function (i.e. stamping, assembly, compression molding, etc.)

• Part loading/unloading

• Safety features

• Footprint and height constraints

• Additional capabilities (i.e. dynamic cushions, heated platens, and more)

Can Beckwood presses handle custom tool and die configurations?

Yes. If you have an existing library of tools and dies that you don’t want to lose, our team can design your new custom press machine for seamless compatibility. If you want to try an all new tool configuration, let us know what you have in mind and our engineers will help you decide the optimal choice for your needs.