Hot Forming Presses

Beckwood manufactures hot forming and superplastic forming (SPF) presses to withstand and thrive in the demanding conditions associated with forming titanium and other high-strength alloys. And we are the only press manufacturer to offer both hydraulic and servo-electric actuation options on our hot forming equipment.

During the hot forming process, both the tool and blank achieve a preheat temperature up to 2,000°F to increase the plasticity and elongation characteristics of the material. The introduction of heat allows for the formation of high-strength materials at significantly lower tonnages when compared to cold forming without the risk of cracking, spring-back, or residual stress.

Superplastic Forming Presses

While some similarities exist between hot forming and superplastic forming, the SPF process has its own unique characteristics. SPF uses extreme temperatures in conjunction with argon gas to form high-strength alloys into complex shapes in a single step. During an SPF cycle, preheated blank material is clamped between a die and a plate. Argon gas, injected through the die into the forming chamber, pushes the blank into the die. The resulting parts have a fine surface finish and are near-net-shape, eliminating the need for secondary finishing. Superplastic forming operations can use a hot forming press as long as the heated platens can maintain temperatures of 2000°F or higher.

Hot Forming Press Options

Common to all Beckwood hot forming or superplastic forming machines are options to efficiently handle the extremely high temperatures inherent to the process. Platens can be fabricated from ceramics, stainless materials, or other exotic metal alloys depending on the specific application requirements. Automated insulated door systems can be provided to efficiently contain the heat within the forming chamber, while also allowing adequate access during part or tool loading and unloading sequences.

Beckwood hot forming and SPF presses provide ultimate precision, optimal temperature control and uniformity, and extreme process repeatability. Our proprietary Active Leveling Control (ALC) also ensures consistent bed-to-ram parallelism despite tool warpage or off-center loading.

Hot Forming / Superplastic Forming Press Features:

- Hydraulic or servo-electric actuation

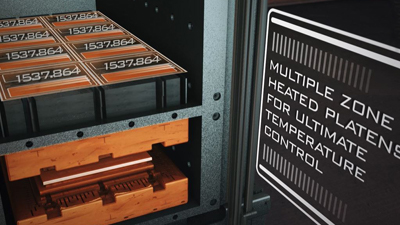

- Electric heating systems with multi-zone temperature control for uniformity across the platen

- Controlled pressure ramping

- Precise gas management (SPF)

- Bed shuttles for simplified tool and part loading and unloading

- Automatic insulated door systems with multi-side access for maximum heat efficiency and easy tool or part loading and unloading

- Pneumatic dwell systems & Variable Frequency Drives for energy efficiency and noise reduction

- Data acquisition systems

- PressLink remote support

- Active Leveling Control

- Press health monitoring systems, including Pre-Preventive Maintenance

VIDEO: See a Hot Forming Press in Action

FAQ: Hot Forming Titanium

Can I convert a cold forming machine into a hot forming machine?

Yes, but a cold forming machine that has been retrofitted to perform hot forming operations lacks controls sophistication, efficiency features, and safety equipment. In addition, structures and components on cold forming machines have not been engineered to withstand the extremely high temperatures inherent in the hot forming process. This increases maintenance costs and the likelihood of operator injury.

How are the platens heated in a hot forming press?

All Beckwood hot form / SPF machines are equipped with multi-zone electric cartridge heaters installed in gun-drilled passages. Embedded thermocouples provide temperature feedback and measure atmospheric temperature, and thermocouple receptacles can be used to measure and record tool temps. This configuration offers uniformity within +/-10°F and allows the user to program temperature off-sets across the length and width of the platen.

What is the recommended start-up and cool-down procedure for the press?

To minimize thermal cycling of the press and its platens as much as possible, heating and cooling in a controlled and gradual manner is necessary. For heating, the general rule is 200°F per hour. For cooling, the standard accepted procedure is turning the heat off, closing the doors, and letting the insulated press naturally cool to an ambient temperature over a long period of time.

How are tool changes performed on a hot forming press?

Tool changes are very similar to other two-piece tool change processes; the main difference is the temperature of the incoming tool. Preheating the tool as much as possible will prevent thermal shock on the platens. If preheating a tool outside of the machine isn’t practical, then putting the tool in the press on steel tubing for a period of time to preheat it before attaching it to the platens is recommended.

What level of control will we have over the hot forming process?

Beckwood’s comprehensive controls platform is designed specifically for high-temperature forming. Recipe handling, cycle profile programming, and remote support are all standard. Data can be stored locally or uploaded to your network, and off-site programming allows engineering or process managers to download recipes directly into the machine for each specific part and production cycle.

How strong is the part when it leaves the press?

The finished parts aren’t as soft as you might think. Typically, the end-user doesn’t need to worry about imprinting material handling features onto the part when removing it from the hot form press. Because the change in temperature between the machine and the ambient plant floor is so significant great, the part cools to a non-soft state almost immediately when the door opens.

What type of safety equipment and PPE is needed on a hot forming press?

In most cases, basic PPE is required for the operator including heat resistant gloves, arm covering, and eye shield. Perimeter guarding and light curtains can be added to the press and workcell to prevent unauthorized personnel from contacting the machine.

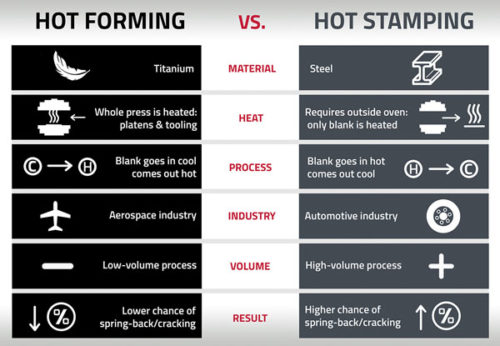

Hot Forming vs. Hot Stamping: What's the Difference?

The terms 'hot forming' and 'hot stamping' are often used interchangeably in the manufacturing industry, but the two processes, and the machinery needed to support them, are actually quite different.

Hot Forming

Hot forming is a process that heats titanium and other high-strength alloys to extreme temperatures which allows them to be formed in the press while in a soft, malleable state. The hot forming process uses heated platens to heat the cold or slightly warmed blank during the press cycle. The introduction of heat inside the press increases the ability to form complex shapes at lower tonnages without the worry of fracturing or spring-back. Because the malleability of the material is increased, hot forming presses are usually much lower tonnages than cold forming presses performing the same function. This is a low volume process, where parts go in cold, come out hot and end in a similar microstructure as they began.

Hot forming is most commonly used to form structural components for the aerospace industry including ribs, engine systems, and landing gear.

Hot Stamping

Hot stamping requires heat outside of the press, includes a quenching step, and changes the microstructure of the steel. The hot stamping process uses an oven to heat the blank, and then the hot blank is transferred into a stamping press, usually via robot or other automated means. The press does not have heated platens, which means a significant higher tonnage is required to form the part correctly. The hot blank is fed into the press and stamped with a die and cooled during the quenching process. Within this quenching process, the crystal structure of the steel transforms from an austenitic phase to a martensitic phase. In the martensitic phase, the carbon atoms are trapped within the structure, resulting in high strength but low-fracture resistance. Hot stamping is a high-volume production with more throughput, but the chance for spring-back and cracking is greater because of the forming and quenching process. The part starts as a low-tensile strength material and comes out as a high-strength and hard material. Hot stamping is most often used in the automotive industry to form door beams, roof rails, body pillars, and tunnel reinforcements.