According to Hoovers, aerospace manufacturing accounts for almost half of U.S. industrial revenue, and it’s no surprise the machines supporting this industry need to be precise, reliable and flexible. Beckwood uniquely understands the complex needs of aerospace suppliers because we serve more of them than any other industry—and have been for decades.

Experience Matters

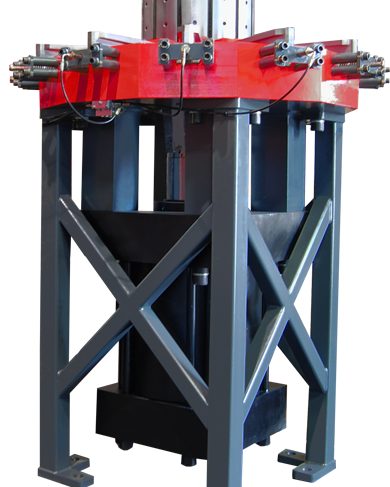

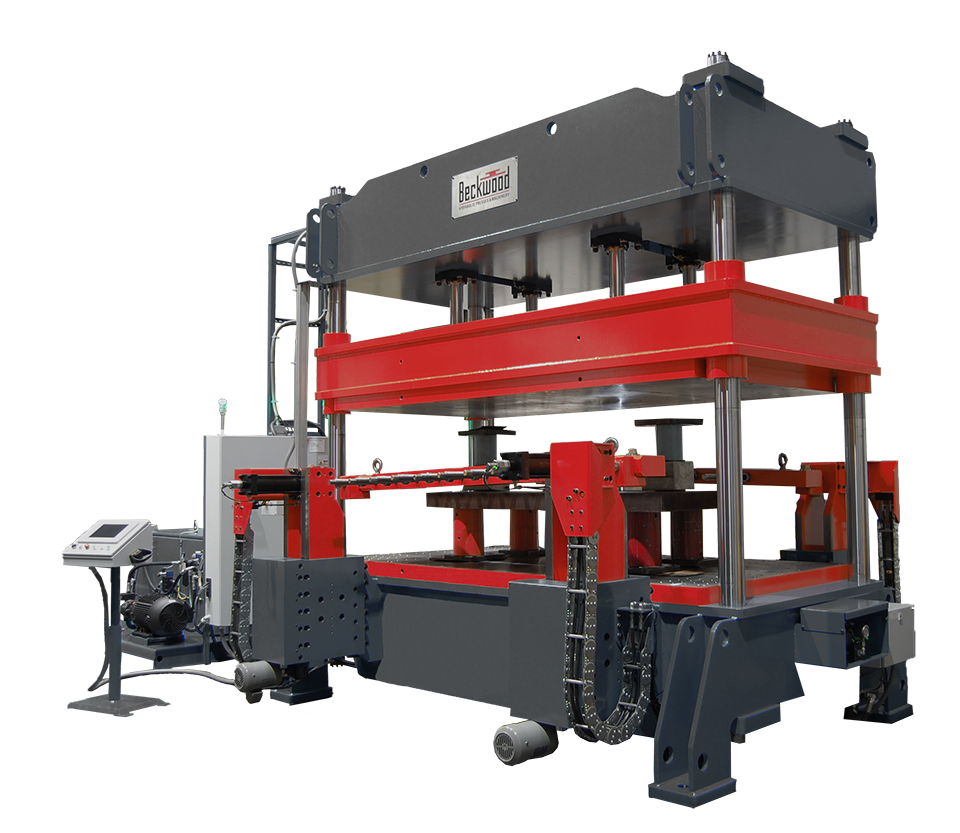

For over 40 years, Beckwood has been designing presses and machinery specifically for the aerospace industry. Our extensive knowledge of industry requirements and supplier needs uniquely positions us as the global leader in aerospace forming equipment. Our machines are commonly used for hot forming/SPF, composite and compression molding, rubber pad forming, sheet hydroforming, draw forming, ring expanding, and stretch forming. We are the only OEM able to build machinery for such a diverse range of aerospace applications, which minimizes sub-tier supplier issues for our customers.

Taking Aerospace Manufacturing to New Heights

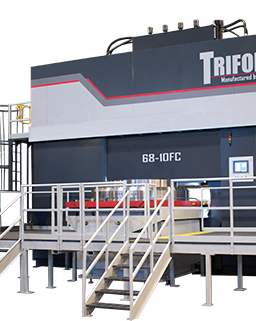

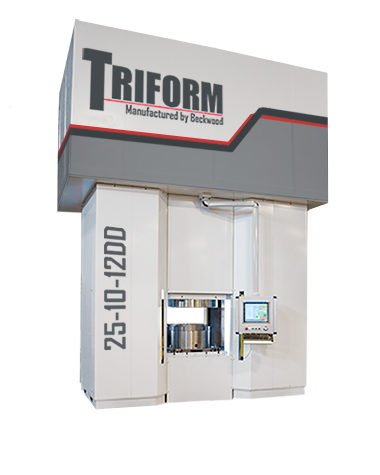

Beckwood is constantly developing new technologies that change the game for aerospace manufacturers. For example, we realized the industry needed easy-to-use, affordable, and reliable sheet hydroforming presses, so we developed the Triform line of specialty forming equipment which includes both fluid cell and deep draw sheet hydroforming machines.

We also incorporate many indispensable features into our presses such as booking rams for ease of mold cleaning or inspection, Active Leveling Control for precise bed-to-ram parallelism despite off-center loading, bed shuttles for safe and easy loading and unloading, dynamic bed cushions for smooth draw forming, and Variable Frequency Drives (VFD) for increased energy efficiency.

It is rocket science

From Fortune 500 aerospace manufacturers to the smallest job shops, Beckwood has extensive experience custom-engineering aerospace manufacturing equipment to help make parts that are stronger and lighter with accurate and repeatable processes. Beckwood presses are highly intuitive and reduce the need for skilled operators, helping manufacturers achieve quality parts with faster turnaround times. The programming technology behind our presses offers unparalleled data monitoring, acquisition, and analysis to ensure process repeatability for years to come.