Fluid Cell sheet hydroforming presses are ideal for making parts with complex geometries, bends, and curves. During a fluid cell cycle, blank sheet material is placed atop a single stationary form block (tool), which rests unsecured on the lower platen or working surface. A pressurized diaphragm filled with hydraulic fluid extends over the tool and blank, expanding as it exerts equal pressure on every point inside the chamber. The result is a near-net-shape part which requires little or no secondary finishing.

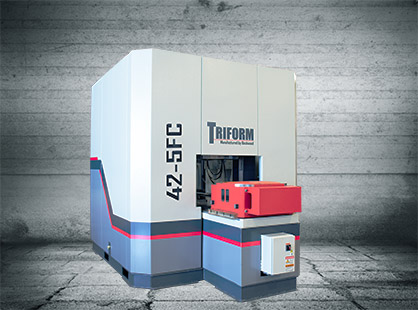

Triform’s fluid cell sheet hydroforming presses come in a variety of sizes to accommodate parts ranging from 2″ to 120” long. Additionally, multiple parts can be formed in a single fluid cell cycle, as long as the tools and blanks fit within the forming area—including parts of different sizes.

Triform fluid cell presses are considered high-performance alternatives to traditional rubber pad forming presses. While pad forming typically applies pressure of ~1,000 – 1,500 PSI on the part, Triform sheet hydroforming presses offer 5,000 – 10,000 PSI. And, unlike traditional pad forming, which applies pressure only on the top surface of the part, Triform presses apply uniform pressure on every square inch of the part.

Dive into hydroforming part formation with this whitepaper.