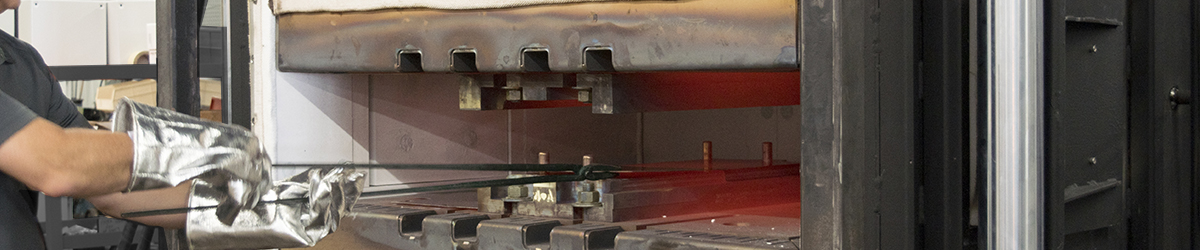

Beckwood has comprehensive experience designing, building, and servicing hydraulic press systems that feature heated platens for compression molding and hot forming/SPF applications. Leverage our extensive heated platen knowledge and improve your processes with heat system upgrades (or additions) to your existing press.

With a heat system upgrade/addition you will gain:

- Precise heat control with the integration of heat to a previously non-heated press system

- Platen cooling capacity for enhanced process control

- Replacement of damaged or warped heated platens

- Enhanced temperature control accuracy, including the potential integration of Beckwood’s multi-zone technology for precise, repeatable mastery over your temperature profile

- Increased temperature capacity (up to 2000°F)

Beckwood is uniquely qualified to upgrade high-temperature platens for hot forming / SPF applications. Platen materials designed for high-temperature forming, such as Duraloy, can be integrated into your press system, allowing for forming temperatures in excess of 2,000°F. Appropriate insulation, including ceramic platen boxes, are frequently integrated to retain heat for maximum efficiency and protect the on-board structural, hydraulic and electrical systems.

Controls upgrades, designed to integrate seamlessly with your press’ heat components, allow you to maximize your heat system upgrades through the introduction of features such as programmable multi-zone temperature control, job storage / recipe handling and data acquisition (DAQ).

Contact our Service Team for a heated platen quotation