| Tonnage | 25 | ||

| Application | Trimming | ||

| Industry | Automotive | ||

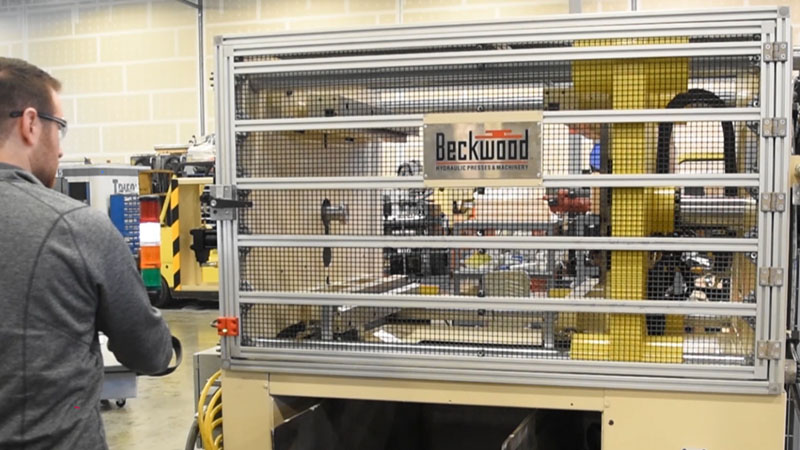

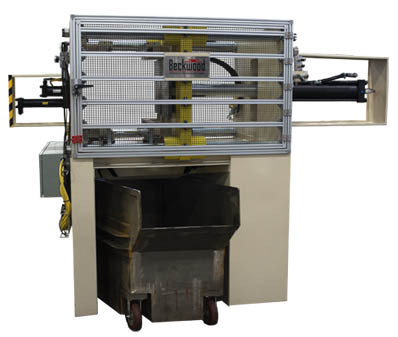

| Frame Style | Non-traditional: 4-Post Horizontal | ||

| Special Features | • Horizontal-acting ram • Ram knockout cylinder • Scrap chute | ||

| Intended Use | Used to trim die cast aluminum parts for the automotive industry |

Custom Features:

- Used to trim die cast aluminum parts for the automotive industry

- (4) 3” diameter chrome housing posts with graphite impregnated bronze bushings for superior ram guidance and rigidity

- 4-Cylinder configuration:

— Main Ram (6” bore, 25” stroke)

— Ram Runner Discharge (2” bore, 10.5” stroke)

— Bed Runner Discharge (2” bore, 10.5” stroke)

— Part Knockout on bed (2.5” bore, 10.5” stroke) - Pneumatic rotary die clamping system prevents dies from leaving the rails during press operation

- Scrap chutes redirect scrap between guide rods into scrap cart

- Hinged safety gate

- Skid mounted power system and reservoir

- Kidney loop filter/cooler circuit with thermostatically-controlled electric fan-powered oil cooler

- Calculated Ram Speeds: Fast Approach:363, Pressing: 161, Return: 290