Beckwood Delivers 9th Press in

Ongoing Partnership with Large Aerospace OEM

Here at Beckwood we’re ecstatic to share that we are gearing up to deliver our 9th press machine to one of the largest aerospace manufacturers in the world over a period of just 3 years. What started as a standalone order for a single division at the OEM has quickly evolved into an ongoing partnership that spans across multiple divisions.

This partnership began in 2022 when one of the OEM’s larger manufacturing divisions ordered 6 hydraulic trimming presses to use in finishing operations for their die-cast parts. These initial hydraulic press machines helped breathe new life into the division’s manufacturing processes by increasing part quality and throughput. Word rapidly spread throughout the company about the success that this division experienced with their Beckwood hydraulic presses.

Just one year later in 2023, another division within the same aerospace company placed an order for two 20-ton EVOx servo-electric press models to be integrated into their automated production line. These models were to replace a pair of hydraulic presses that used hard stops to compensate for their unreliable press accuracy. With the two new EVOx models, this division was able to completely eliminate the need for those hard stops and improve forming repeatability to a reliable degree without the use of any external components. They noticed that their production line had also become much quieter, not just due to the removal of the hard stops but as a result of their new servo-electric presses operating at a much lower volume than the previous machines.

“About a year ago we ordered two 20-ton servo presses for our factories and loved them thus far. Now that we’re running production, management is now pushing to get another press.”

– A purchasing representative at this aerospace OEM regarding ordering the division’s 3rd EVOx press

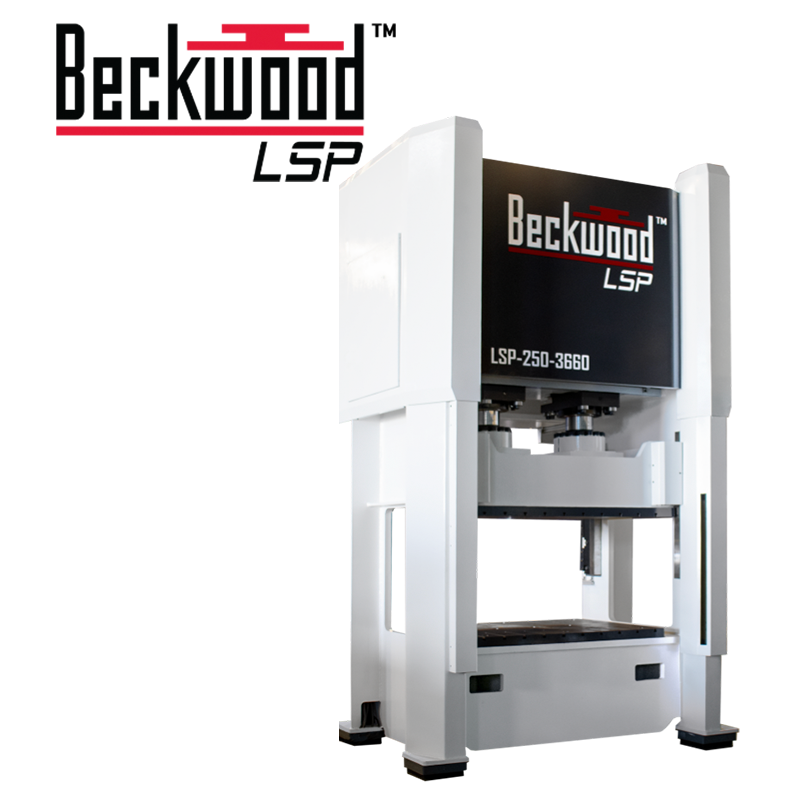

Now in 2024, that same division has made the call that they’re ready to begin scaling their operations by investing in another EVOx press which is identical to the two that they previously ordered. Part of the reason they were able to do this can be attributed to the floor space that they saved by making the switch to servo-electric, as these presses tend to have a smaller shop footprint than their hydraulic counterparts.

At Beckwood we pride ourselves on having the versatility required to meet the two divisions’ vastly different needs with solutions that are custom tailored to their exact applications. By strategically developing our hydraulic and linear servo-electric press technologies alongside each other, we have positioned ourselves as the ideal manufacturer to meet the wide range of manufacturing needs of this aerospace OEM.

Regarding the partnership between Beckwood and this aerospace manufacturing mogul, Sales Engineer Gerard Choinka had this to say:

“When that original lead came in a few years ago… you just dream of getting a lead like that. From the excitement of getting that original lead that came in to actually building them 9 machines now is awesome. Becoming a Tier 1 supplier for them within their organization is what I can see happening in the future- and hopefully, we’re their go-to press equipment supplier for them moving forward.”

– Gerard Choinka, Sales Engineer at Beckwood