| Tonnage | 50 | ||

| Application | Spotting/Tryout, General Forming | ||

| Industry | R&D; Education | ||

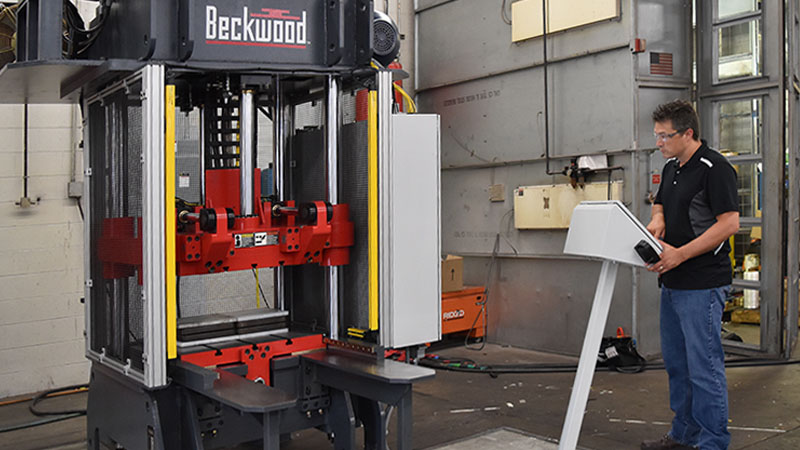

| Frame Style | 4-Post | ||

| Special Features | • 30” x 30” bed shuttle • 90-degree booking ram | ||

| Intended Use | Used in a classroom setting to teach die maintenance |

Custom Features:

- (4) 4” diameter chrome housing posts with graphite impregnated bronze bushings for superior ram guidance and rigidity

- 30” x 30” hydraulic bed shuttle equipped with audible alarm, stationary consoles, and alignment tracks for efficient loading and unloading through the front opening of the press

- Booking ram with 90-degree booking capability for dies up to 2,000 lbs

- Light curtains guarding the front opening of the press; bolt-on expanded metal guarding on the sides and rear of the press

- Crown mounted power system and reservoir

- Kidney loop filter/cooler circuit with thermostatically-controlled electric fan-powered oil cooler

- Calculated ram speeds: Pressing: 52 IPM; Return: 77 IPM