Hydraulic Presses and Servo Technology for the Defense Sector

The defense sector calls for the absolute best that the manufacturing world has to offer. In American defense manufacturing there is no room for error, so having a hydraulic press that guarantees precision and performance is crucial. Whether the challenge at hand is hot forming titanium, deep drawing high temp alloys, or compression molding composite components, Beckwood provides the ideal hydraulic presses for your defense manufacturing needs.

Beckwood Press offers hydraulic presses, servo-electric presses, and forming machines designed to tackle the rigorous challenges faced by military manufacturers. Learn about how Beckwood’s high-quality machinery ensures that your defense manufacturing never misses the mark.

Beckwood’s SAM Registration: Streamlining Government Procurement

- CAGE / NCAGE: 7FNR4

- DUNS Number: 079419673

Hydraulic Presses and Servo Technology for the Defense Sector

The defense sector calls for the absolute best that the manufacturing world has to offer. In American defense manufacturing there is no room for error, so having a hydraulic press that guarantees precision and performance is crucial. Whether the challenge at hand is hot forming titanium, deep drawing high temp alloys, or compression molding composite components, Beckwood provides the ideal hydraulic presses for your defense manufacturing needs.

Beckwood Press offers hydraulic presses, servo-electric presses, and forming machines designed to tackle the rigorous challenges faced by military manufacturers. Learn about how Beckwood’s high-quality machinery ensures that your defense manufacturing never misses the mark.

Beckwood’s SAM Registration: Streamlining Government Procurement

- CAGE / NCAGE: 7FNR4

- DUNS Number: 079419673

Custom Hydraulic Presses

for Military Manufacturers

Beckwood specializes in engineering and building custom hydraulic presses for every manufacturing challenge, including those faced by military manufacturers. This often means designing solutions that do not fit within a standard configuration in order to meet the unique needs and space requirements of specialized manufacturing facilities. A custom press engineered for your specific application and production facility will give you a competitive edge and prove its ROI faster than you might expect. In addition to custom frame styles, custom-engineered hydraulic presses can also improve accuracy, efficiency, safety, and uptime depending on the options chosen during the design phase. For the defense sector, we offer heated platen for easier high temp metal and superplastic forming; multi-action press beds for peak forming accuracy; and gib guided rams to ensure an even delivery of force every time.

Custom Hydraulic Presses

for Military Manufacturers

Beckwood specializes in engineering and building custom hydraulic presses for every manufacturing challenge, including those faced by military manufacturers. This often means designing solutions that do not fit within a standard configuration in order to meet the unique needs and space requirements of specialized manufacturing facilities. A custom press engineered for your specific application and production facility will give you a competitive edge and prove its ROI faster than you might expect. In addition to custom frame styles, custom-engineered hydraulic presses can also improve accuracy, efficiency, safety, and uptime depending on the options chosen during the design phase. For the defense sector, we offer heated platen for easier high temp metal and superplastic forming; multi-action press beds for peak forming accuracy; and gib guided rams to ensure an even delivery of force every time.

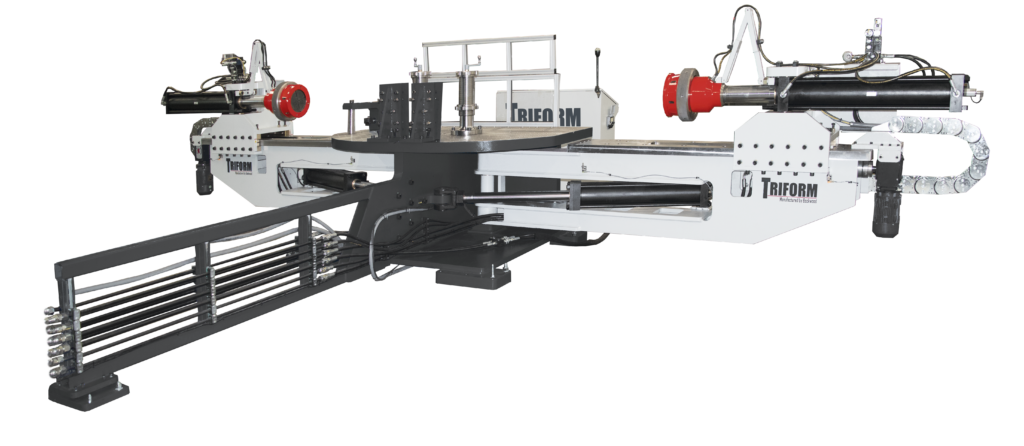

TRIFORM Hydroforming Hydraulic Presses

Going beyond traditional press equipment, Beckwood has the expertise in specialized aerospace forming equipment thanks to the ingenuity of our TRIFORM Engineers. Beckwood’s Triform™ sheet hydroforming presses thrive in low-volume, high-mix production environments where tool changes occur frequently and manufacturing processes are continually refined. Sheet hydroforming presses use a pressurized rubber diaphragm and a single, un-mated tool to create near-net-shape parts in just one cycle. Triform’s proprietary In-Sight software even allows you to view forming progress at any point throughout a cycle and adjust the recipe to achieve optimum forming results. This feature greatly expedites R&D and reduces costs and scrap.

Triform’s deep drawing hydraulic presses use an intuitive controls system in conjunction with a pressurized elastomeric diaphragm to form domes and hemispheres up to 12” deep in a single cycle. The flexible diaphragm acts as a universal female die half to reduce tooling costs by up to 90%. Diaphragm pressure and punch position can be tightly controlled (to 1% of full scale and +/-0.002” respectively), resulting in smooth, uniform, scratch-free parts with no secondary finishing required. The strict control of material flow also eliminates wrinkles and tears. Beckwood has produced deep draw sheet hydroforming hydraulic presses for rapid part prototyping, production of high-performance aircraft parts for the defense sector, and military manufacturing of aerospace engine parts.

TRIFORM Ring Expanders for the Defense Sector

A ring expander forms symmetrical, ring-shaped parts commonly used in the aerospace and defense industries for turbine engine manufacturing. Hydraulic ring expanders are typically used to prepare piston rings for installation in an engine, where they must be precisely sized and shaped to provide a proper seal between the piston and cylinder wall. Overall, hydraulic ring expanders are an effective tool for expanding metal rings quickly and uniformly with minimal risk of damaging the ring or causing uneven expansion. Heating capabilities can be integrated into the ring forming system to help with hard to form alloys and tempering requirements. The ring expanding process minimizes material thinning and virtually eliminates the stress point issues associated with traditional rolling and machining. These rings can be made from a variety of high-strength materials including Inconel, Hastelloy and Titanium, among others.

TRIFORM Stretch Forming Equipment for American Defense Manufacturing

Stretch forming is a type of metalworking most commonly used by aerospace and military manufacturers. This process can produce parts of varying complexity, from a simple curved part such as an aircraft skin to one with intricate geometries consisting of non-uniform cross sections. Most leading edge parts, joined structural sections, and contoured trim are created using a stretch forming machine. The main advantage of the stretch forming process is the ability to form large metal sheets and extrusions into complex shapes in a single cycle. Work hardening is a byproduct of the stretch forming process resulting in parts with a higher tensile strength and minimal springback. Since sheet and extrusion stretch forming machines use a single die, mated tooling is not required–saving up to 50% on tooling costs compared to traditional forming methods. Additionally, parts are free from scratches and scuffs, so secondary finishing is not required.

Beckwood Presses for Hot Forming & Superplastic Forming

Beckwood hot forming and SPF presses provide ultimate precision, optimal temperature control and uniformity, and extreme process repeatability. Common to all Beckwood hot forming or superplastic forming machines are options to efficiently handle the extremely high temperatures inherent to the process. Platens can be fabricated from ceramics, stainless materials, or other exotic metal alloys depending on the specific application requirements. Automated insulated door systems can be provided to efficiently contain the heat within the forming chamber, while also allowing adequate access during part or tool loading and unloading sequences.

During the hot forming process, both the tool and blank achieve a preheat temperature up to 2,000°F to increase the plasticity and elongation characteristics of the material. The introduction of heat allows for the formation of high-strength materials at significantly lower tonnages when compared to cold forming without the risk of cracking, spring-back, or residual stress.

SPF uses extreme temperatures in conjunction with argon gas to form high-strength alloys into complex shapes in a single step. During an SPF cycle, preheated blank material is clamped between a die and a plate. Argon gas, injected through the die into the forming chamber, pushes the blank into the die. The resulting parts have a fine surface finish and are near-net-shape, eliminating the need for secondary finishing.

Today, modern Hot Form and SPF systems can be equipped with all electric linear servo actuators in lieu of hydraulics to add precision performance with NO HYDRAULIC FLUID, thereby minimizing maintenance and improving safety. Existing hydraulic press systems can also be retrofitted with linear servo actuators for modernization.

Compression Molding Presses for Military Manufacturers

A compression molding press can be used to compress, cure, and form plastic, rubber, SMC, BMC, and composites for military manufacturers to make products they use every day. Beckwood’s compression molding presses are engineered specifically to maximize process efficiency. From maintaining consistent heat throughout a specified dwell period to precision pressure ramping, managing burp cycles, and collecting specific cycle data for part quality verification, Beckwood heated presses help you perfect your forming operation. From plastic components like instrument panels and engine covers; to metal components including hood liners, performance brake pads, and bearings; to even power sources like solid state batteries; compression molding presses provide the versatility to serve every facet of the automotive industry.

Linear Servo Press Technology for American Defense Manufacturing

Complex draw work and stamping high-strength alloys require tight process control. With Beckwood LSP™, you can easily program ram position, travel distance, and speeds for maximum productivity. With instant feedback for diagnostics and data acquisition to record and measure torque, force, position, and time, no press offers more precision or better part quality. With presses ranging from 125 – 500 tons, Beckwood LSP™ offers the highest tonnage capacity of any linear servo press available. High precision, uptime, reliability, and unmatched forming flexibility are pillars of this world-class press technology. The use of a servo motor and linear motion system allows for greater control over the pressing process, including the ability to adjust the press force, speed, and stroke. This makes linear servo presses ideal for stamping of high-strength steels, complex draw forming, progressive die forming, assembly, and any application that requires high-precision and/or accuracy.

BECKWOOD HYDRAULIC PRESSES: BORN IN THE USA

Beckwood presses are proudly made in the USA and shipped to manufacturers worldwide. At Beckwood, we’re not just a technology company; we’re a pioneer in American-made hydraulic presses, servo-electric presses, and hydroforming equipment. Since 1976, our commitment to manufacturing presses in the United States has resulted in machines that are safe, reliable, and easy to maintain and support. Every Beckwood press is engineered and built in the U.S.A. at our 55,000+ sq. ft. headquarters in St. Louis, Missouri, solidifying our pledge to support American defense manufacturing and reshoring efforts. For the pinnacle of manufacturing quality and unrivaled customer support, Beckwood is the only way to go.