Highly-Versatile Press Designs

A 4-post hydraulic press is one of the most common combinations of frame style and actuation type because of its versatility. Due to the flexibility of a hydraulic system, these machines can achieve large amounts of force over a small forming area or small amounts of force over a large forming area. With a 4-post hydraulic press, there are virtually no restrictions on tonnage or bed size. And when used in conjunction with Beckwood’s proprietary Active Leveling Control System, they maintain precise bed-to-ram parallelism even during off-center loading applications. This versatility coupled with the ability to accommodate dies of any size makes 4-column presses ideal for nearly every industry and application.

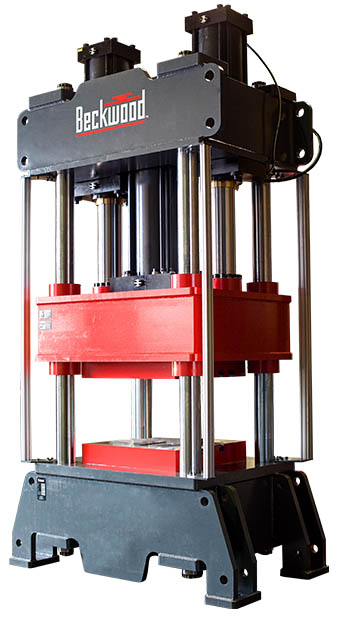

Parts of a 4-Post Press

A four-post press is composed of a crown weldment, ram weldment, and bed weldment joined together by steel posts on all four corners. These machines offer ultimate access to all sides of the working area and tonnage capacities up to 10,000+ tons. Hydraulic systems can be crown-mounted or skid-mounted with ease to accommodate any footprint requirements, and forming areas vary widely from very small to very large depending on the application. Whether you choose hydraulic or servo-electric actuation, each 4-post press is guided by replaceable, graphite-impregnated bronze bushings and solid, chrome-plated posts to ensure years of maintenance-free, reliable operation. Beckwood’s precision bushings provide superior ram guidance and eliminate the need for external lubrication.

For additional forming flexibility, options like heated platens, bed cushions, high-speed motion controllers, quick die change systems, and automation components can be added to a 4-post hydraulic press easily and cost-effectively. If your company prioritizes safety, we can also add light curtains, hard guarding, perimeter guarding, area scanners, die clamps, and redundant ram holders.

ARTICLE: Columbia Metal Spinning Relies on 450-ton 4-post hydraulic press

Learn about the benefits of servo-electric actuation