| Tonnage | 20 | ||

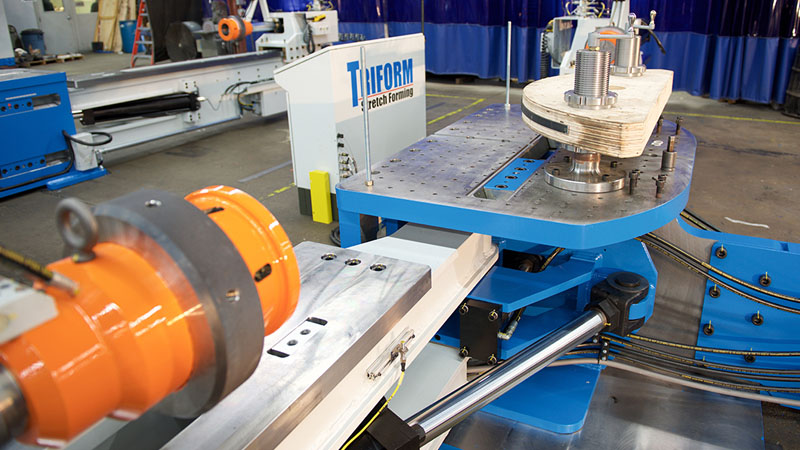

| Application | Stretch Forming | ||

| Industry | Aerospace | ||

| Frame Style | Non-traditional | ||

| Special Features | • Integrated tool heating • Independently controlled arms | ||

| Intended Use | Used to stretch and contour aerospace alloys into a variety of roll formed profiles |

Custom Features:

Maximum Part Length: 240”; Minimum Part Length: 8” (w/ 4” chucks)

Close Capability: 10”

Tension Cylinder Stroke: 30”

Tension Cylinder Speed: 1-30 IPM (Programmable)

Tension Cylinder Rotation: +/- 25 Degrees

Swing Angle: 10 Degrees Forward / 90 Degrees Backward

Maximum Operating Pressure: 3,000 PSI

Integrated Tool Heating Included

Operating Temperature Range: 350ºF – 800ºF

Heat Control Integrated into System HMI Control