| Tonnage | 75 | ||

| Application | Punching/Blanking | ||

| Industry | General Manufacturing; Roll Forming | ||

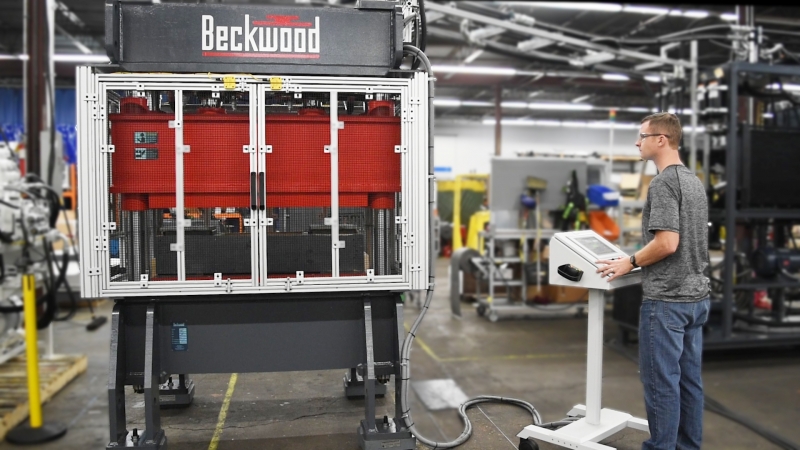

| Frame Style | 4-Post | ||

| Special Features | • Ultra Fast Ram Speeds • Vibration Dampening Pads • Scrap Chute | ||

| Intended Use | Used to punch aluminum and steel in a roll forming production line |

Custom Features:

- (4) 4” diameter chrome housing posts with graphite impregnated bronze bushings for superior ram guidance and rigidity

- 30” x 50” bed & ram bolsters

- Ram speeds capable of 60 strokes/minute

- Programmable fixed stops for fast ram retract

- 6” x 24” scrap chute in the bed weldment

- Hydraulic circuit is specifically designed for short cycling of the press

- Bolt on expanded metal guards with safety interlocks cover the front, side & rear openings

- Skid mounted power system and reservoir

- Kidney loop filter/cooler circuit with thermostatically controlled fan motor

- Vibration dampening leveling pads provided to absorb mechanical energy for overall system protection