Beckwood presses are remarkably durable and engineered to achieve unprecedented up-time in order to meet the demanding requirements of today’s 24-7 manufacturing environments. We design each hydraulic press frame to the Infinite Life classification using Finite Element Analysis (FEA) design software. The resulting computer-aided simulations, which mirror real-world manufacturing stresses, ensure the design is robust enough to handle the most taxing industrial applications.

What is FEA?

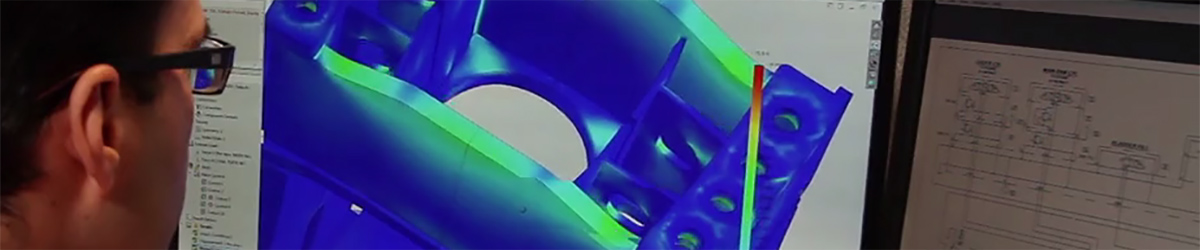

Finite Element Analysis (FEA) is a computerized method for predicting how a structure will react to real-world forces (vibration, heat, fluid flow, and other physical effects). FEA works by breaking down a real object into a large number of finite elements and using mathematical equations to predict the behavior of each element. A computer then calculates the individual element behaviors to predict the behavior of the actual object. A structure is classified as “Built for Infinite Life” when its stress levels are reduced enough to eliminate the effects of fatigue on the specified material.

Benefits of FEA Testing

Using SolidWorks Simulation to replicate real-world scenarios, Beckwood engineers are able to evaluate press performance, improve product quality, and test new ideas before a single piece is manufactured. Testing against a broad range of parameters (durability, static and dynamic response, assembly motion, heat transfer, fluid dynamics, etc.) during the design process ensures your press is engineered for maximum uptime.

Mastering the Process

Beckwood’s Sales and Structural Engineering teams work with each customer to determine the characteristics of their tooling and the intended application for the press. From this information, they are able to create a 3D model which is tested in SolidWorks against the Infinite Life standards. If at any point during the engineering process the structure does not meet the Infinite Life classification, the hydraulic press design is modified to account for structural deflection and stress – before approval drawings are ever submitted to the customer.