What Auto Manufacturers Need

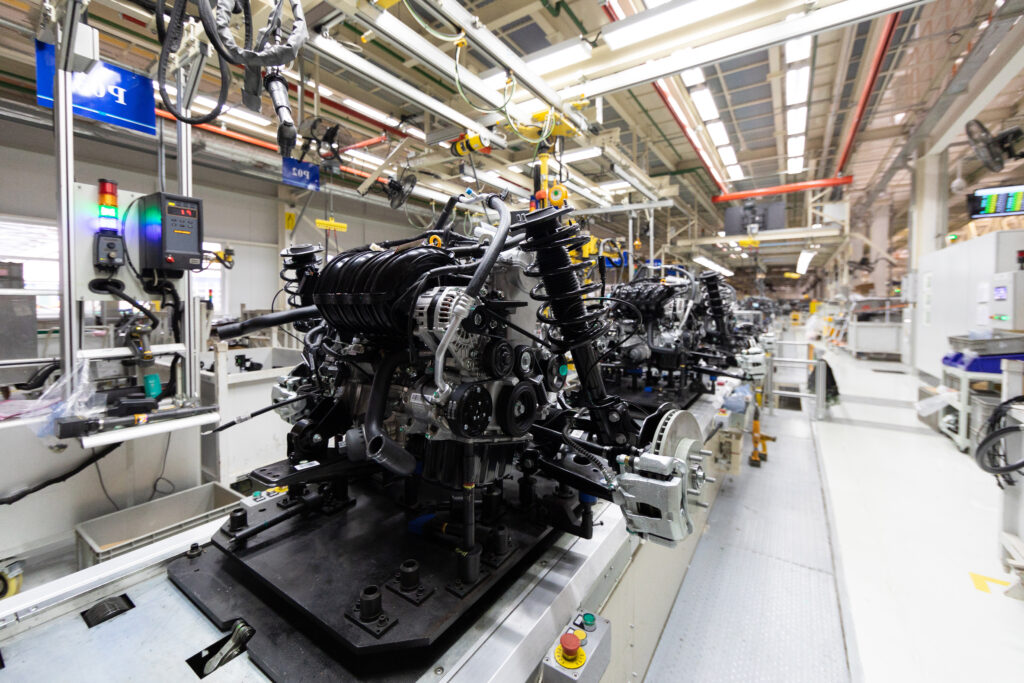

The automotive industry handles a wide range of materials, from delicate foams and plastics to high-strength metals and composites. With such a wide range of production methods to cover, automotive manufacturers need presses that are versatile enough to handle their varied workloads. Beckwood’s presses are engineered to maximize efficiency, no matter what type of operation your automotive manufacturing facility performs. Discover how our high-performance machinery can take your automotive production to the finish line in record time

What Auto Manufacturers Need

The automotive industry handles a wide range of materials, from delicate foams and plastics to high-strength metals and composites. With such a wide range of production methods to cover, automotive manufacturers need presses that are versatile enough to handle their varied workloads. Beckwood’s presses are engineered to maximize efficiency, no matter what type of operation your automotive manufacturing facility performs. Discover how our high-performance machinery can take your automotive production to the finish line in record time

No time to idle?

Start your new press build today!

The Electric Revolution – EVOx™ and LSP™

EVOx™

Beckwood’s EVOx™ line of c-frame and 4-post servo-electric presses offers a low-maintenance alternative to traditional hydraulic systems while delivering the accuracy and precision your application requires. Servo-electric presses use an all-electric actuation system in lieu of hydraulics or mechanical flywheels to precisely control the ram throughout the entire stroke. Eliminating the hoses, pumps, and hydraulic oil improves cleanliness, energy efficiency, and operator safety while lowering operational and maintenance costs. With standard models ranging from 5,000 lbf to 100,000 lbf (2.5 to 50 tons), EVOx presses make low-tonnage part formation and assembly easy.

The Electric Revolution – EVOx™ and LSP™

EVOx™

Beckwood’s EVOx™ line of c-frame and 4-post servo-electric presses offers a low-maintenance alternative to traditional hydraulic systems while delivering the accuracy and precision your application requires. Servo-electric presses use an all-electric actuation system in lieu of hydraulics or mechanical flywheels to precisely control the ram throughout the entire stroke. Eliminating the hoses, pumps, and hydraulic oil improves cleanliness, energy efficiency, and operator safety while lowering operational and maintenance costs. With standard models ranging from 5,000 lbf to 100,000 lbf (2.5 to 50 tons), EVOx presses make low-tonnage part formation and assembly easy.

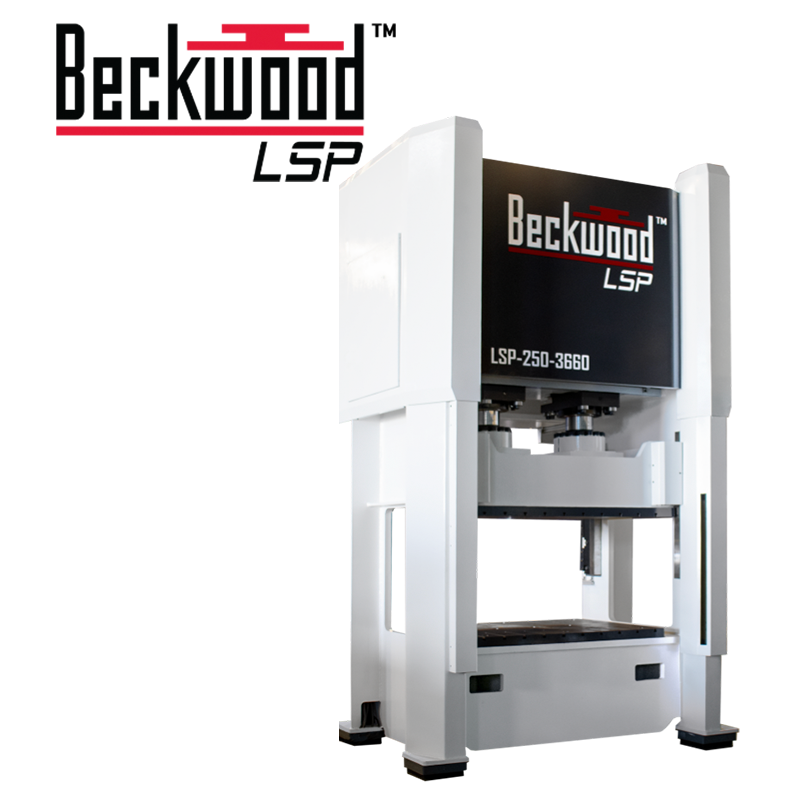

LSP™

Stretch forming is a type of metalworking most commonly used by aerospace and military manufacturers. This process can produce parts of varying complexity, from a simple curved part such as an aircraft skin to one with intricate geometries consisting of non-uniform cross sections. Most leading edge parts, joined structural sections, and contoured trim are created using a stretch forming machine. The main advantage of the stretch forming process is the ability to form large metal sheets and extrusions into complex shapes in a single cycle. Work hardening is a byproduct of the stretch forming process resulting in parts with a higher tensile strength and minimal springback. Since sheet and extrusion stretch forming machines use a single die, mated tooling is not required–saving up to 50% on tooling costs compared to traditional forming methods. Additionally, parts are free from scratches and scuffs, so secondary finishing is not required.

Ascent™ Standard Automotive Press Machines

Beckwood’s Ascent™ line of standard hydraulic presses is pre-engineered for fast shipment and cost efficiency. Through our standardization of the press designs, Ascent customers realize up to 50% lower cost and lead time compared to custom machinery, without sacrificing quality or performance. All Ascent models feature a unitized frame designed to the Infinite Life classification and a gib guidance system for ultimate precision and rigidity. These gib guided systems can be used to form both interior and exterior automotive components, including plastic molded, painted and assembled parts. These parts are used for instrument and door panels, headliners, rear gates, exterior cladding and more.

Compression Molding Presses

A compression molding press can be used to compress, cure, and form plastic, rubber, SMC, BMC, and composites for the automotive industry to make the products we use every day. Beckwood’s compression molding presses are engineered specifically to maximize process efficiency. From maintaining consistent heat throughout a specified dwell period to precision pressure ramping, managing burp cycles, and collecting specific cycle data for part quality verification, Beckwood heated presses help you perfect your forming operation. Whether you’re forming plastic components like instrument panels and engine covers; metal components including hood liners, performance brake pads, and bearings; or even power sources like solid state batteries; compression molding presses provide the versatility to serve every facet of the automotive industry.

Custom Hydraulic Presses

Beckwood specializes in engineering and building custom presses for every manufacturing challenge, including fully custom automotive press machinery. This often means designing solutions that do not fit within a standard configuration in order to meet the unique needs and space requirements of specialized manufacturing facilities. A custom press engineered for your specific application and production facility will give you a competitive edge and prove its ROI faster than you might expect. In addition to custom frame styles, custom-engineered presses can also improve accuracy, efficiency, safety, and uptime depending on the options chosen during the design phase. Beckwood has developed a variety of custom hydraulic presses for automotive manufacturers, including this trimming press for interior components.