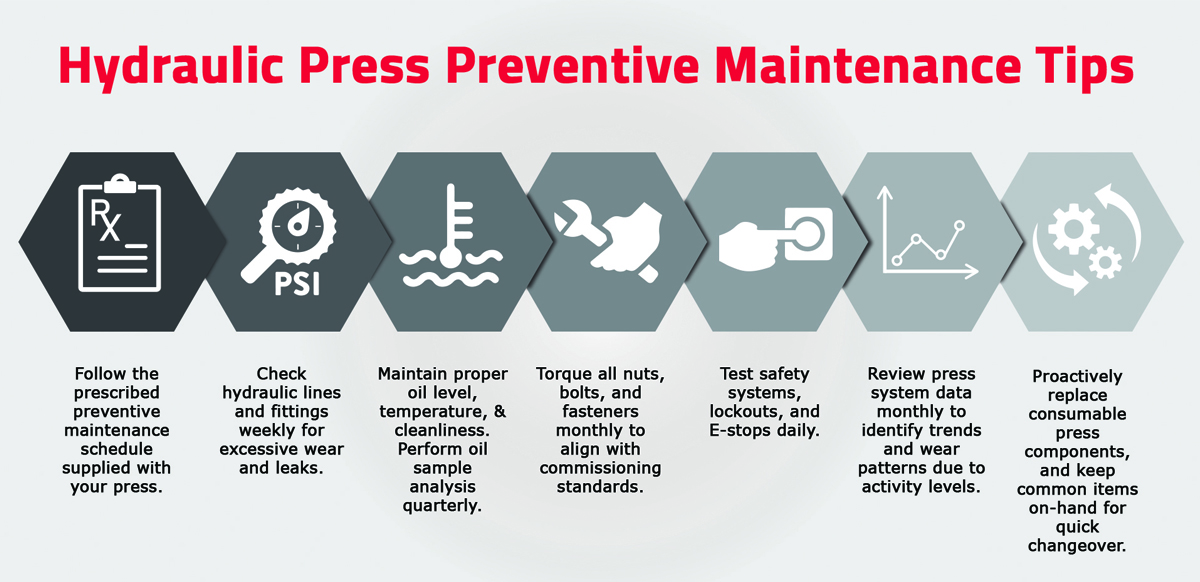

The best way to prevent unplanned downtime on a hydraulic press is with proactive, preventive maintenance. Below are several tips to keep your hydraulic press running smoothly.

- Follow the prescribed hydraulic press preventive maintenance schedule supplied with your press – Different presses with varying capabilities require special maintenance. While most hydraulic presses share the same core needs for maintenance, it is always best to start by following the specific schedule supplied in your machine manual.

- Check hydraulic lines and fittings regularly for leaks – Small leaks can lead to large problems and large messes. If a leak is detected, tighten or replace the hose or fitting and monitor the correction.

- Check for proper oil level and operating temperature – Improper oil levels can lead to pump inefficiency due to cavitation, where air enters the liquid being pumped. Oil that runs too hot can lead to premature breakdown. Monitoring oil temperature also serves as a warning that circuit components may not be performing optimally. Press systems that traditionally run cool and suddenly change to run hot likely have a failing component that is passing oil and adding heat to the system.

- Ensure oil cleanliness – Contaminated oil can cause significant component damage, unplanned downtime, and complete system failure. Basic hydraulic systems often run with simple return-line filtration circuits (10-micron filters), but higher-performing systems using proportional or servo valves require cleaner filtration (6-micron filters) in conjunction with in-line pressure and return-line filters. The type of system and required cleanliness should be specified by the manufacturer. Periodic oil sampling is suggested and can be analyzed by a third party or dedicated oil-testing service. Often, your local hydraulic-component distributor can perform this duty or suggest a reliable company.

- Mind the fasteners – Whether the press frame is all-welded construction or a tie-rod model, it relies on numerous nuts and bolts for proper operation. Monitor cylinder attachment monthly. Once the bolts have been checked to the proper torque, baseline marks can serve as at-a-glance indicators for future monitoring. Many presses carry marks on all attachment bolts when the bolts have been certified to the proper torque. Also, monitor bolster-plate fasteners and tie-rod pre-tensioning nuts.

- Monitor the safety system on a daily basis – Press systems with light curtains, interlocking gates, safety mats, etc., should be tested prior to operation. If a safety device has been found defective or unreliable, lockout the press and perform service immediately. Also, test the E-stop safety circuit daily.

- Record press data – Data logging, though not often used, is one of the best tools for monitoring press-system performance. Recording items such as operating pressures during rapid-advance, pressing and rapid-retract portions of the press cycle can provide valuable data as to press-system efficiency. Your equipment manufacturer should capture this data during equipment testing and report it to you. Ideally, record this data when the press is commissioned and refer back to it periodically. If you see increases in operational pressures, components are performing below optimum levels and may have begun to fail.

- Be proactive in replacing press components – Most presses are constructed of several hydraulic components either from a single manufacturer or from multiple companies. Each manufacturer has an expected service life for each component. Replacing components proactively before a failure occurs prevents unexpected downtime and costly repairs. Hydraulic components (especially pumps) can fail and contaminate the hydraulic system. It is far easier and less costly to replace components on a regular basis than to wait for a component to fail and possibly contaminate the system.

Learn about the importance of oil cleanliness

Talk to a Service Tech about maintenance for your hydraulic press