Beckwood’s Ascent™ line of standard hydraulic presses is pre-engineered for fast shipment and cost efficiency. Through our standardization of the press designs, Ascent customers realize up to 50% lower cost and lead time compared to custom machinery, without sacrificing quality or performance.

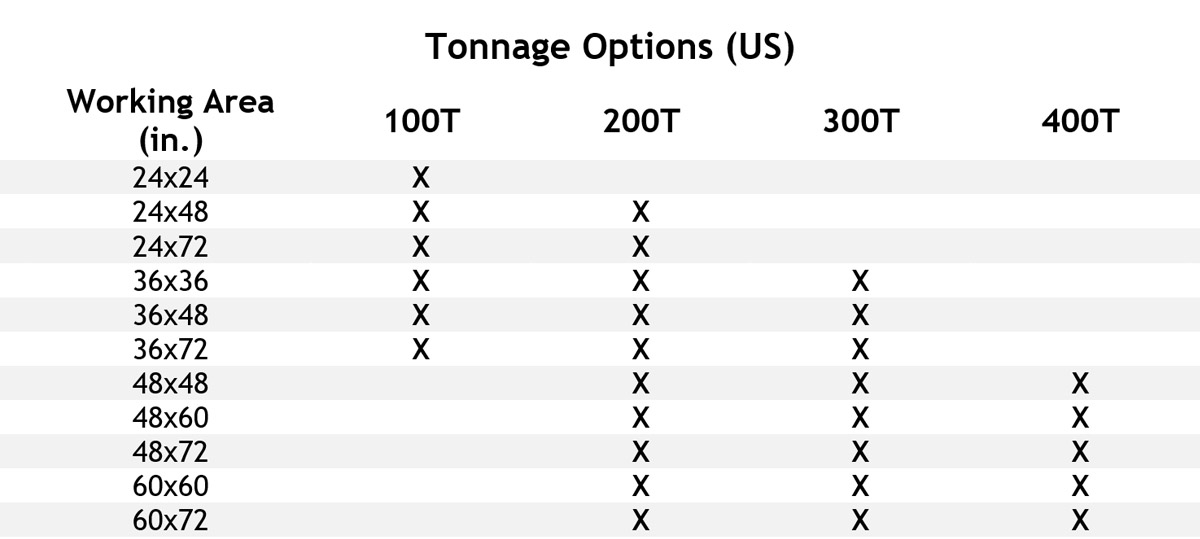

All Ascent models feature a unitized frame designed to the Infinite Life classification and a gib guidance system for ultimate precision and rigidity. With models ranging from 100 tons to 400 tons, a wide range of frame sizes, and options for added safety and uptime, this line is highly customizable to meet the demands of any manufacturing facility. No matter the industry or forming process, an Ascent press will improve your production.

All Ascent presses are manufactured, serviced, and supported in the USA by our industry-leading team of factory-trained experts, so you can rest assured knowing your press is backed by Beckwood.

Don’t see a model to fit your needs? Get a custom quote!