| Tonnage | 75 | ||

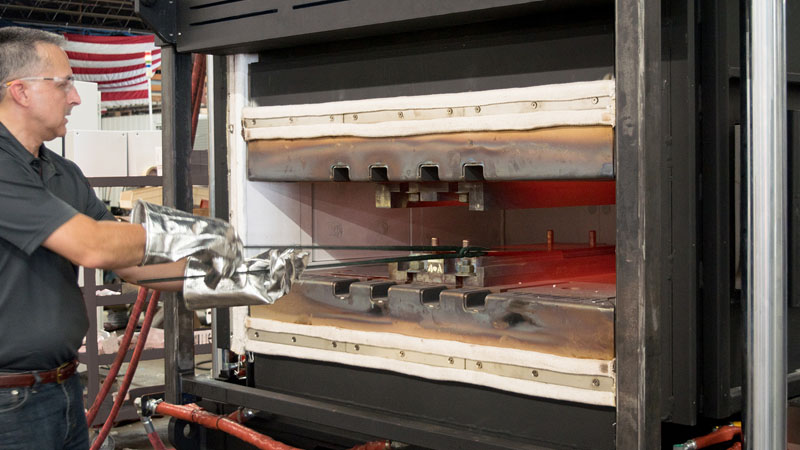

| Application | Hot Forming/SPF | ||

| Industry | Aerospace | ||

| Frame Style | 4-Post | ||

| Special Features | • High-Temperature Heated Platens • Automatic Insulated Doors • 3-Cylinder Configuration | ||

| Intended Use | Used to hot form titanium parts in the aerospace industry |

Custom Features:

- (4) chrome housing posts with oversized poured/cast ram guide bushings for superior ram guidance and rigidity

- 3-cylinder configuration for increased precision and safety

- (2) 30” x 48” Duraloy TMA-4505 electrically-heated platens with multiple zones of temperature control up to 1,600-degree F

- Gun drilled channels in the platens create a serpentine flow for rapid cooling

- Insulated automatic door system grants 4-sided access while maximizing heat efficiency

- Kidney loop filter/cooler circuit with thermostatically-controlled water-oil heat exchanger

- Calculated Ram Speeds: Pressing: 0.125-90 IPM; Return: 0-120 IPM