-

How Ring Expanders and Stretch Forming Equipment Save Time

Discover the advantages of domestic manufacturing in the hydraulic press industry. From quality control to local expertise, Beckwood gives a competitive edge.

-

Industry Insight – Hydraulic Press Automation

Discover the advantages of domestic manufacturing in the hydraulic press industry. From quality control to local expertise, Beckwood gives a competitive edge.

-

The Benefits of Domestic Manufacturing

Discover the advantages of domestic manufacturing in the hydraulic press industry. From quality control to local expertise, Beckwood gives a competitive edge.

-

EVOx Servo Presses Deliver Unmatched Precision

Beckwood’s EVOx servo electric press has proven to be a key player in precision metalforming. Learn more what makes this press Beckwood Tough.

-

Optimize Lead Time & Cost with an Ascent Hydraulic Press

Beckwood’s standard Ascent line is anything but. Learn how these presses slash lead times with astute engineering backed by decades of experience.

-

Maximize Daily Efficiency with an Electric Press

Electric presses are made to set your business up for daily success. Minimize scrap, reduce energy use, & spend less downtime with an electric Beckwood press.

-

How Linear Servo Press Technology Is Revolutionizing Aerospace Hot Forming and SPF Applications

Linear servo press technology developed by Beckwood ramps up production in aerospace forming by eliminating the downsides of working with hydraulic fluid.

-

Choosing the Best Features for Your Custom Hydraulic Press

Selecting the right features in your custom hydraulic press can slash downtime, save costs, and skyrocket productivity. Learn what Beckwood has to offer.

-

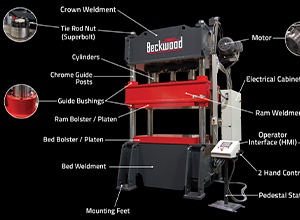

Press Anatomy

Dive deep into the parts of a press, press anatomy, and terminology. This article includes information regarding press components, press technology, and press controls so you can make informed decisions about your press needs.

-

Whitepaper: Understanding Sheet Hydroforming

Sheet hydroforming is an essential process for low-volume, high-mix part production. But what exactly goes into achieving crisp geometries with a hydroforming press? Learn what drives successful part formation with pros/cons of the hydroforming methods, material flow control, blank design, and more.

-

Whitepaper: Composite Forming and Light-Weighting Guide

Composites are quickly becoming the industry standard over materials like steel, titanium, concrete, wood, but researching the right press to form composites correctly can be difficult. This whitepaper gives tips, tricks, and information on how to form the best lightweight composite parts from presses to methods.

-

Whitepaper: Hydraulic Vs. Servo-Electric Presses

Both hydraulic and servo-electric presses offer a variety of advantages and disadvantages that could be the deciding factor for your purchase. Before choosing any kind of press, it is important to compare the two presses and understand which best supports the needs of your facility.

-

Whitepaper: Choosing the Right Heating Method for Your Application

Adding heat to a forming operation can yield an array of benefits, but choosing the right heat specifications for your application is challenging. This whitepaper evaluates each method of press heating as well as several alternative heating techniques to ensure you have the best machinery for the job.

-

Titanium Forming Methods

Learn about the various titanium forming methods including cold forming, hot forming, and superplastic forming. Discover how to choose the best method and machinery for your operation.

-

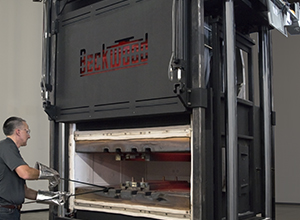

e-Book: The Beginner’s Guide to Hot Forming Titanium

Insourcing your titanium forming operations isn't as difficult as you might think, but you need to know the basics of the hot forming process first. Download this e-book to learn how to get started with hot forming.

-

Preventive Maintenance Tips for Your Hydraulic Press

Taking care of your hydraulic press with preventive maintenance measures can be the single most important factor in increasing your machine's uptime and overall life. Simple preventive maintenance measures can insure your press operates optimally as long as possible.

-

Oil Cleanliness

Keeping your hydraulic oil clean and contaminate free impacts the uptime of a hydraulic system more than any other preventive maintenance measure. Contaminated oil leads to extended downtime at best and major system failure if corrective actions are not taken.

-

Whitepaper: Guide to Press Automation

Automating presses for maximum productivity and increased throughput is one of the biggest challenges manufacturers face. From conveyors and pick-and-place systems to robots, cobots and IIoT-connected machinery, this whitepaper explores various ways to automate presses and how to know when your operation is ready for automation.

-

Buying a New Vs. a Used Press

What do you need to know before deciding to purchase a used or new hydraulic press? Beckwood understands the appeal used equipment has to certain manufacturers. The short lead times and lower up-front purchase prices of used hydraulic presses can be attractive.

-

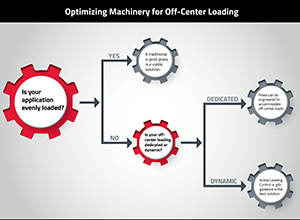

Off-Center Loading

Bed-to-ram parallelism is important to your press structure, hydraulic systems and tooling. Some operations, however, require you to load your press unevenly. How can you counteract this?

-

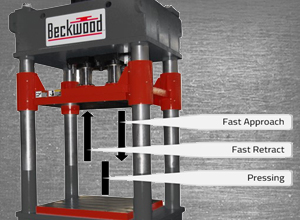

Understanding Ram Speed and Cycle Profiles

Fast approach, pressing speed, fast retract and stripping force - what do all of these terms mean? How can you translate that information into the number of cycles per minute a press can perform?

Blog

Articles and whitepapers to improve your process knowledge